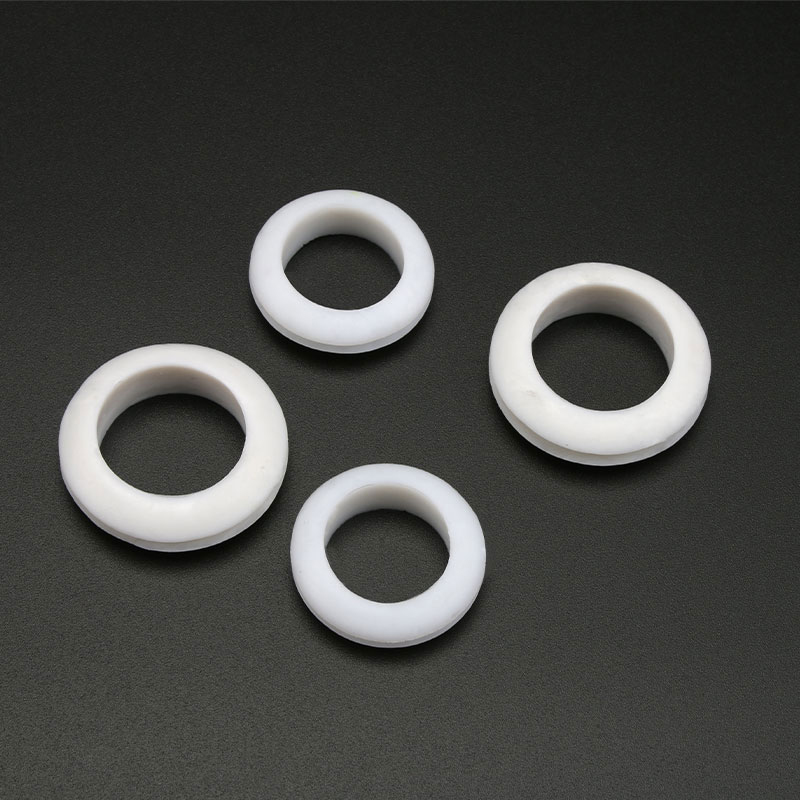

A rubber grommet is a circular or oval-shaped ring made of flexible rubber material. It is designed to fit into holes in panels, providing a protective lining. These grommets serve a wide range of functions, including cushioning, sealing, and preventing wear or abrasion caused by friction. Rubber grommets are used to insulate and protect sensitive wires and cables that pass through metal or plastic surfaces, preventing damage and wear from contact with the edges of the holes.

1. Benefits of Rubber Grommets

There are several significant benefits of using rubber grommets in a wide range of applications:

Protection from Wear and Tear: Rubber grommets protect wires and cables from abrasive surfaces. When installed in a hole or gap, they cushion and shield the sensitive parts from mechanical damage caused by movement, vibrations, or contact with sharp edges.

Vibration Dampening: One of the key benefits of rubber grommets is their ability to absorb and dampen vibrations. This is particularly important in automotive and industrial applications, where vibration can cause excessive wear and reduce the lifespan of equipment or components.

Sealing Properties: Rubber grommets provide an effective seal to prevent the ingress of dust, dirt, water, and other contaminants. This sealing feature is crucial in applications where environmental factors could negatively affect the performance or longevity of electrical or mechanical components.

Electrical Insulation: Rubber grommets offer excellent electrical insulation properties, preventing short circuits by keeping wires and cables away from metallic surfaces. This is especially important in environments where electrical safety is a priority.

Durability and Flexibility: Rubber is a flexible and durable material that can withstand extreme temperatures, chemical exposure, and other harsh environmental conditions. Rubber grommets maintain their effectiveness over long periods, even in challenging environments.

Cost-Effectiveness: Rubber grommets are affordable components that provide significant protection, durability, and reliability. Their relatively low cost makes them an attractive solution for manufacturers and engineers looking to improve product quality without increasing costs.

2. Applications of Rubber Grommets

Rubber grommets are versatile components that find applications in numerous industries. Some of the primary applications include:

Automotive Industry: Rubber grommets are widely used in cars and other vehicles for protecting wires and cables from abrasion and preventing electrical failures. They also reduce noise and vibrations in automotive assemblies.

Electrical Industry: Grommets are essential in protecting electrical wires and cables that pass through metal panels. The rubber helps to prevent the sharp edges of metal from cutting into the insulation of the wires, ensuring that the electrical connections are safe.

Construction: In the construction industry, rubber grommets are used to protect pipes and wires running through structural components, such as concrete walls or steel beams. These grommets help to absorb shock and prevent long-term damage.

Marine Industry: Grommets are used to protect electrical cables and wires in boats and ships, as they provide effective sealing and protection against water ingress, ensuring reliable performance even in harsh marine environments.

Industrial Manufacturing: Rubber grommets are used to protect sensitive components from damage during the assembly or operation of machinery. They provide vibration damping and can be used to reduce noise levels in machines.

By selecting the appropriate material and type, businesses and manufacturers can enhance the reliability and efficiency of their products while reducing the potential for wear and tear.

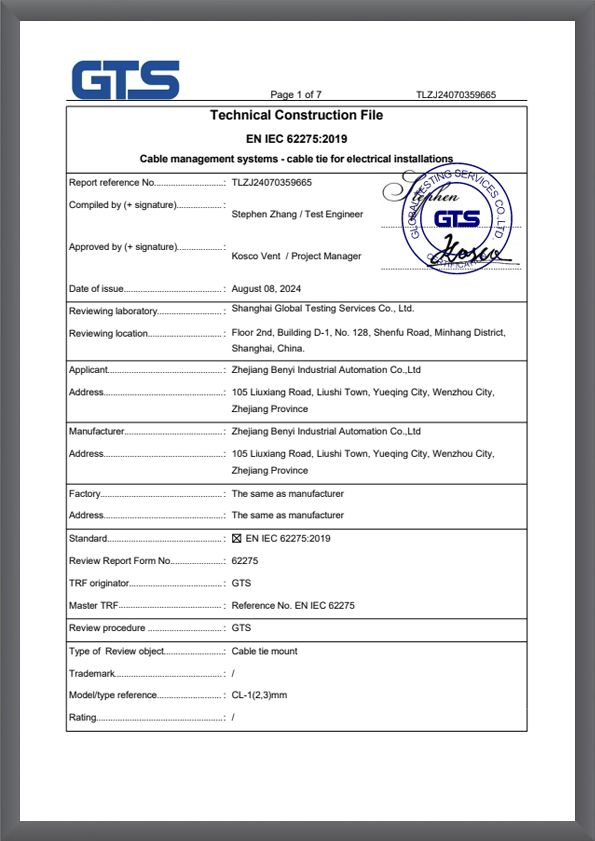

TLZJ24070359665

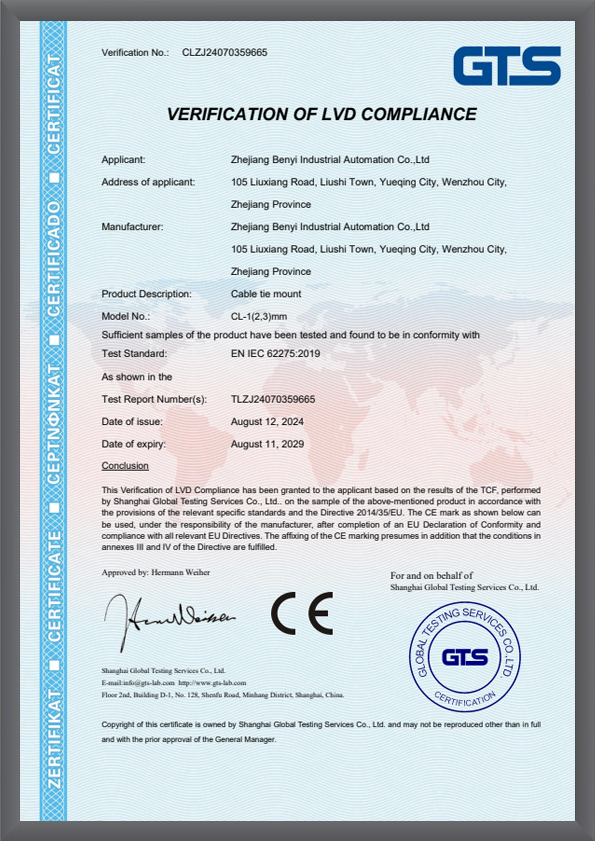

TLZJ24070359665 CLZJ24070359665

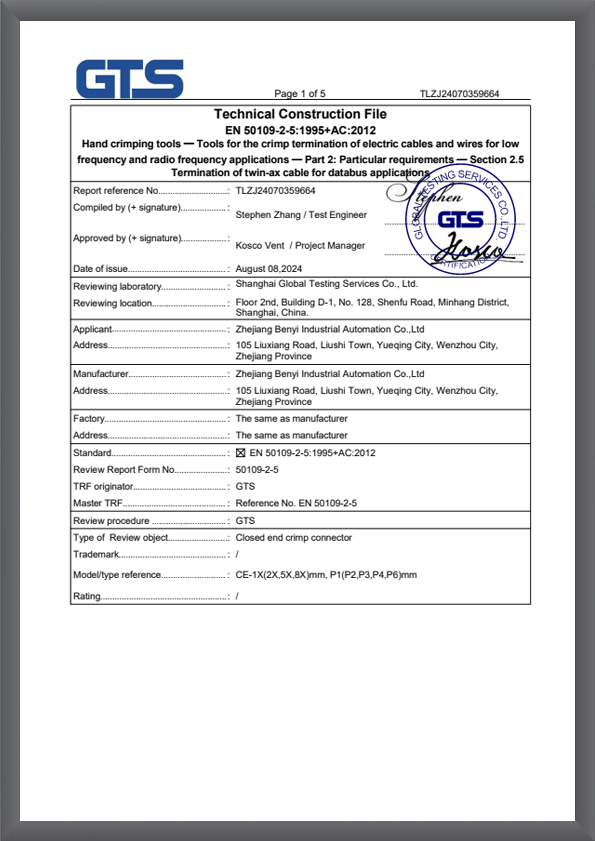

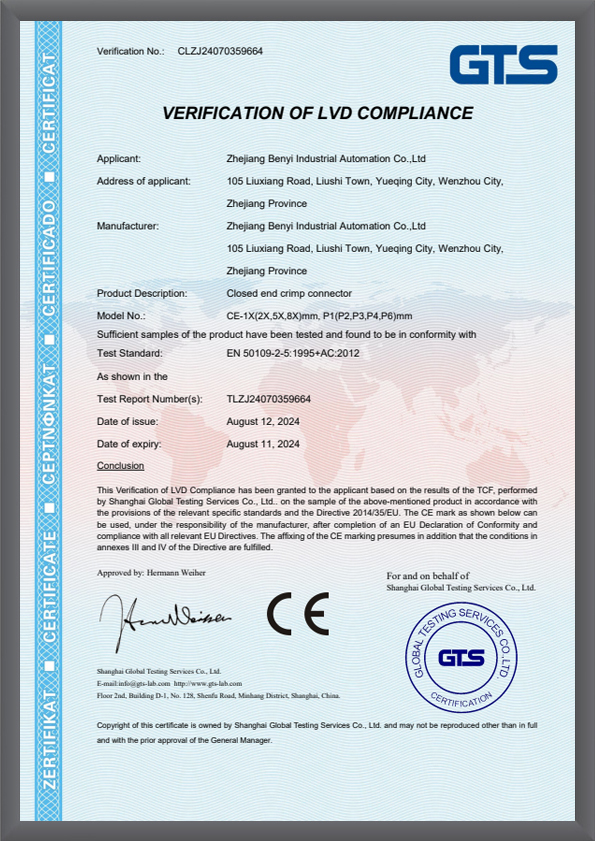

CLZJ24070359665 TLZJ24070359664

TLZJ24070359664 CLZJ24070359664

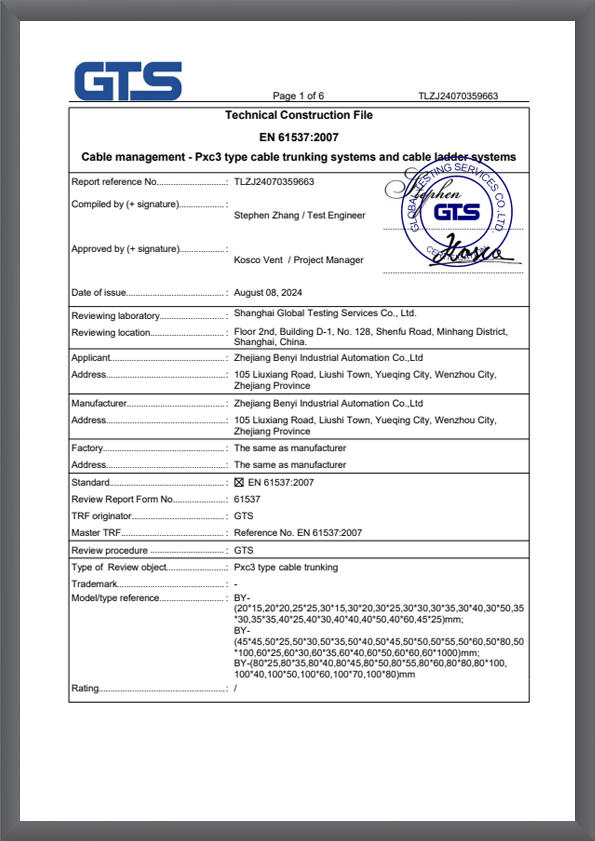

CLZJ24070359664 TLZJ24070359663

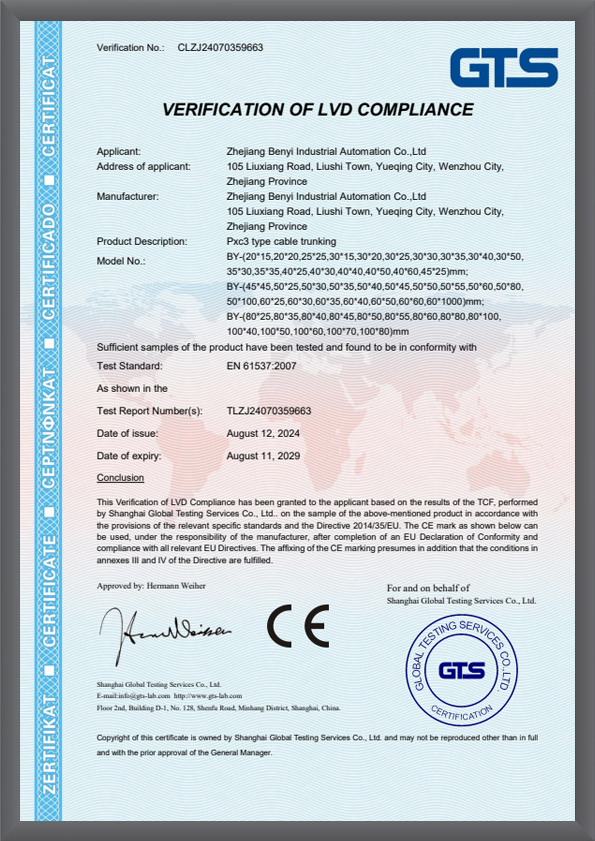

TLZJ24070359663 CLZJ24070359663

CLZJ24070359663 英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语