Web Menu

Product Search

Exit Menu

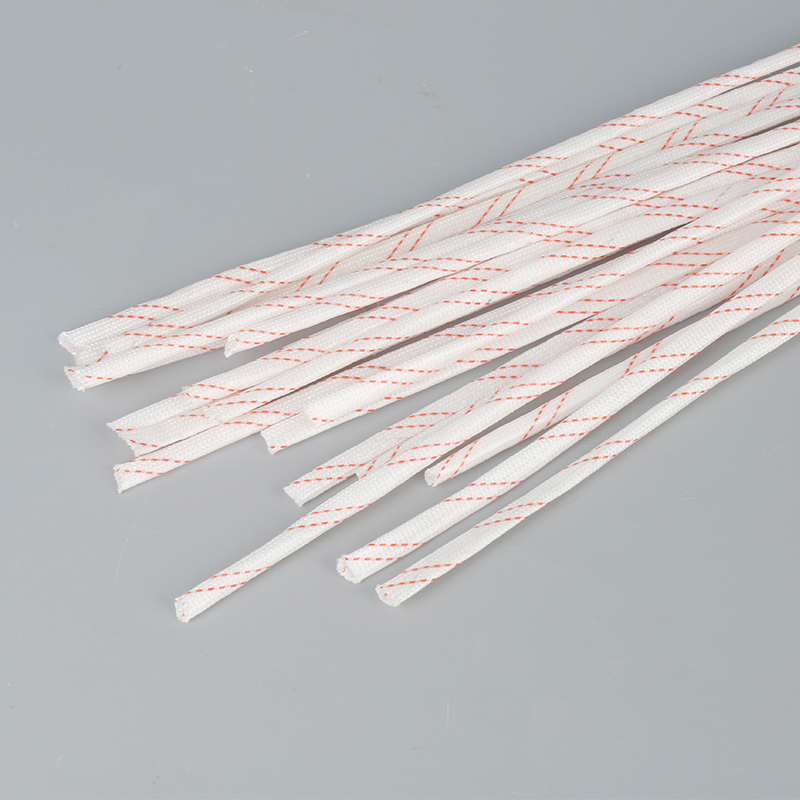

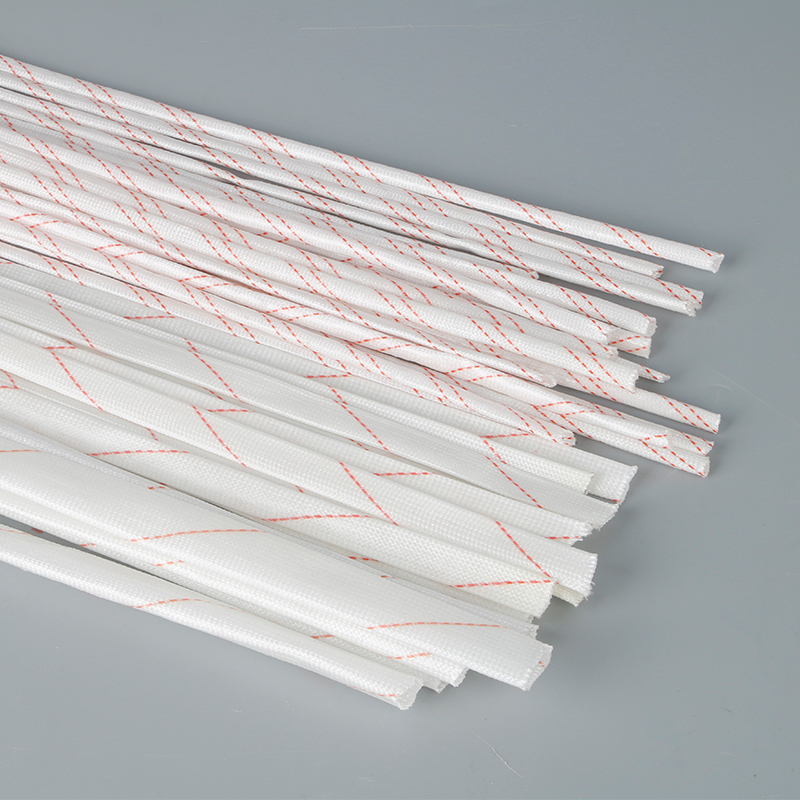

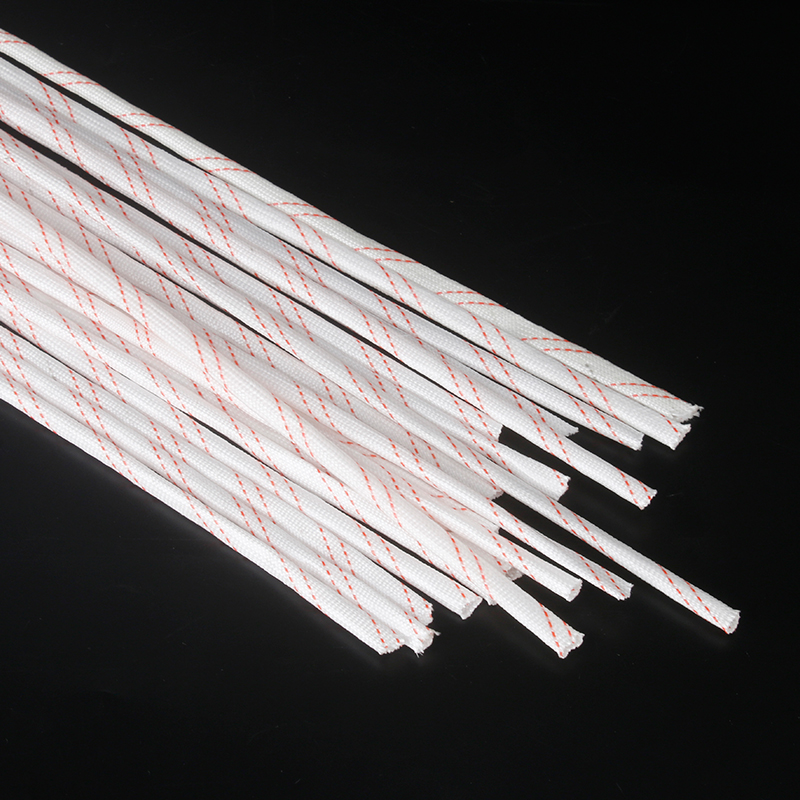

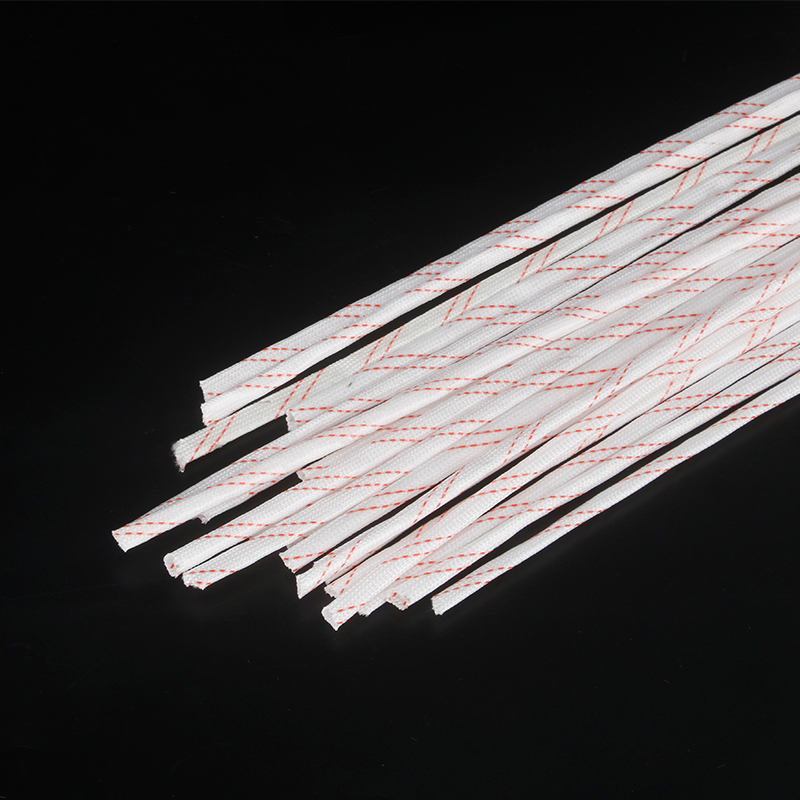

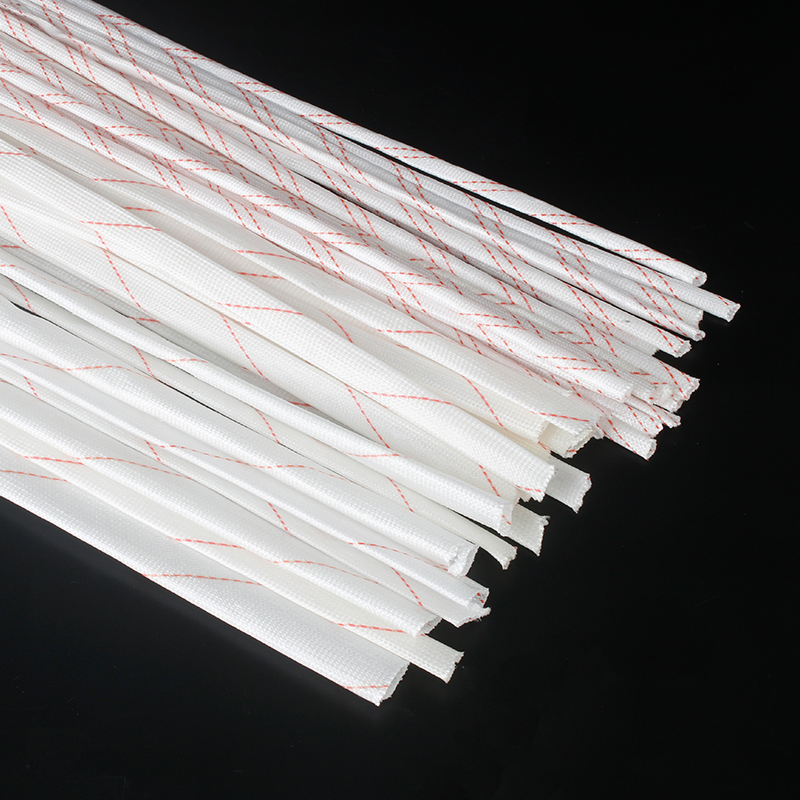

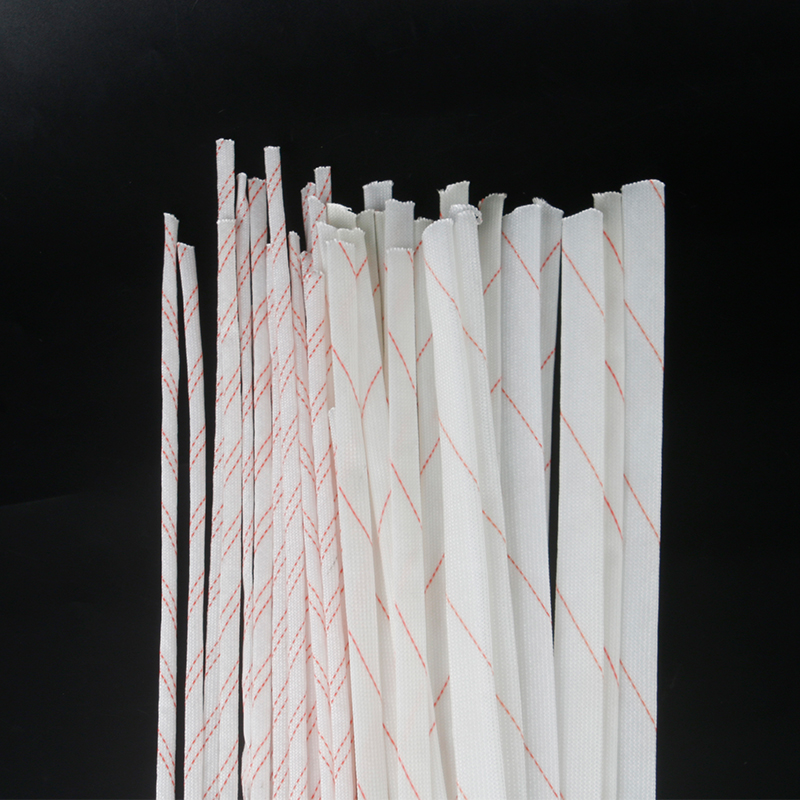

Fiberglass Heat Sleeve For Sale

Fiberglass sleeves are versatile and durable protective materials widely used in various industrial applications, ranging from electrical insulation to thermal protection. These sleeves are made of high-quality woven fiberglass, which is coated with various resins to enhance their performance. Their excellent mechanical properties, heat resistance, and electrical insulation make them ideal for use in extreme conditions.

1. Composition and Manufacturing Process

Fiberglass sleeves are primarily made of woven fiberglass fabrics that are treated with specialized resins, including silicone, epoxy, or polyurethane coatings. The fiberglass itself is a non-metallic material composed of fine glass fibers. When woven, these fibers create a mesh that offers high tensile strength and resistance to wear. The resin coating adds further strength, flexibility, and protective properties, making the sleeve suitable for harsh environments.

The manufacturing process involves weaving the fiberglass strands into a fabric, followed by coating the fabric with resin. The coated fabric is then heat-treated to ensure that the resin hardens, bonding the fibers together to create a sturdy, durable sleeve. The sleeve is often available in various diameters, lengths, and thicknesses to meet different application requirements.

2. Key Features of Fiberglass Sleeves

a. High Heat Resistance

One of the most significant advantages of fiberglass sleeves is their excellent heat resistance. Depending on the coating and construction, these sleeves can withstand temperatures ranging from 250°C to 1000°C. This makes them suitable for use in high-temperature environments, such as automotive engines, industrial machines, and electrical components.

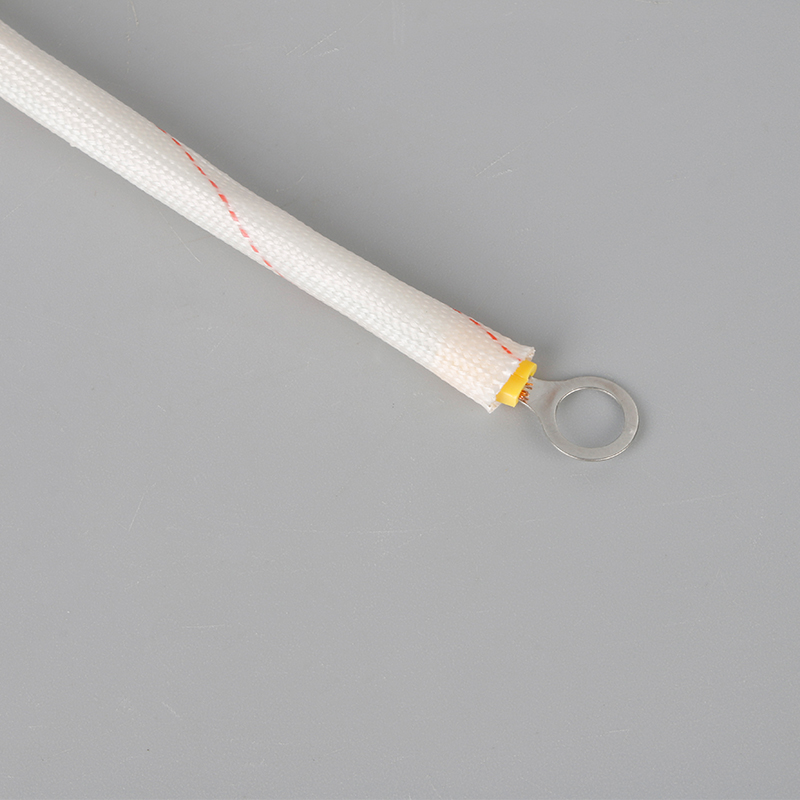

b. Electrical Insulation

Fiberglass sleeves are widely used for electrical insulation because of their high dielectric strength. The sleeves prevent short circuits, electric shocks, and other electrical hazards by offering superior insulation properties. They are commonly used in wiring, cables, transformers, and other electrical equipment to ensure safety and reliability in both low and high-voltage applications.

c. Mechanical Strength and Durability

The fiberglass material offers excellent tensile strength, making the sleeves highly resistant to mechanical wear, abrasion, and impact. This mechanical strength is particularly important in industries such as construction, manufacturing, and automotive, where components are exposed to physical stress and wear.

d. Chemical Resistance

Fiberglass sleeves are resistant to a wide range of chemicals, including acids, alkalis, and oils. This feature makes them suitable for use in environments where chemicals or solvents are present. Their resistance to corrosion and chemical degradation ensures that the sleeves maintain their structural integrity over time, even in harsh industrial environments.

e. Flexibility and Ease of Installation

Despite their mechanical strength, fiberglass sleeves are relatively flexible and easy to install. They can be used to wrap around wires, cables, or other components without difficulty. The sleeves can also be cut to various lengths, allowing for customizable applications. The flexibility of the material helps ensure that it can be applied to a wide variety of shapes and sizes.

Fiberglass sleeves are an essential component in many industries, offering a combination of heat resistance, electrical insulation, mechanical strength, and chemical resistance. Whether used for protecting electrical components, shielding cables from physical damage, or preventing fire hazards, fiberglass sleeves provide reliable protection in a wide variety of applications. Their versatility, durability, and cost-effectiveness make them a popular choice for businesses seeking long-lasting solutions for their protective material needs.

About Us

Honor

-

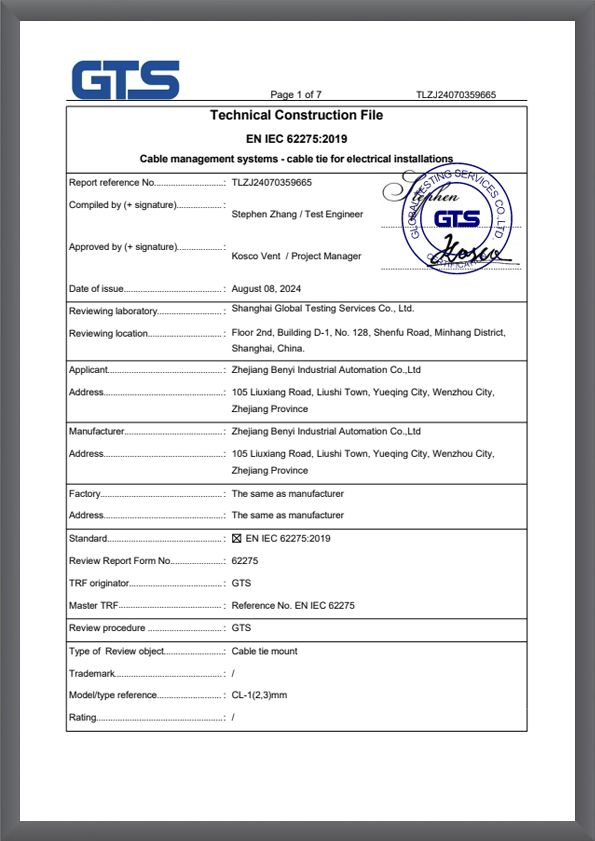

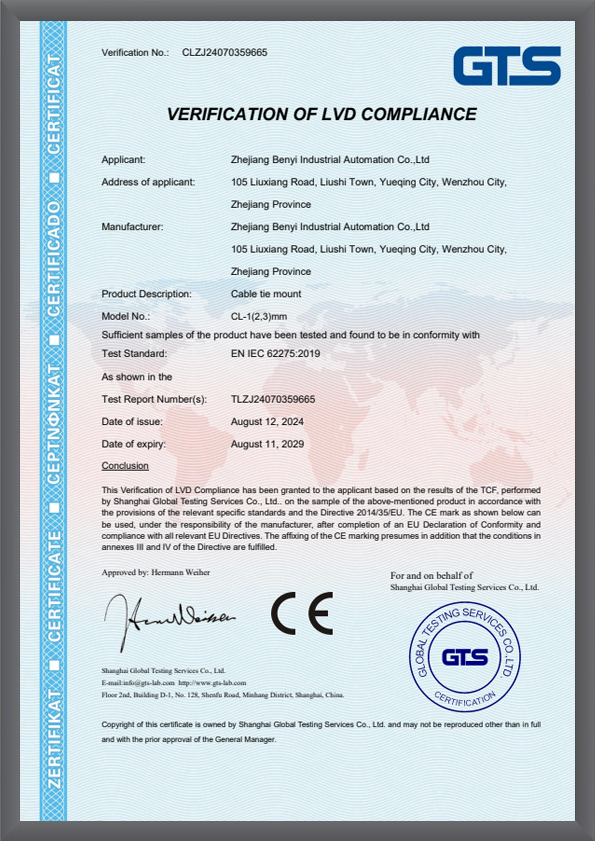

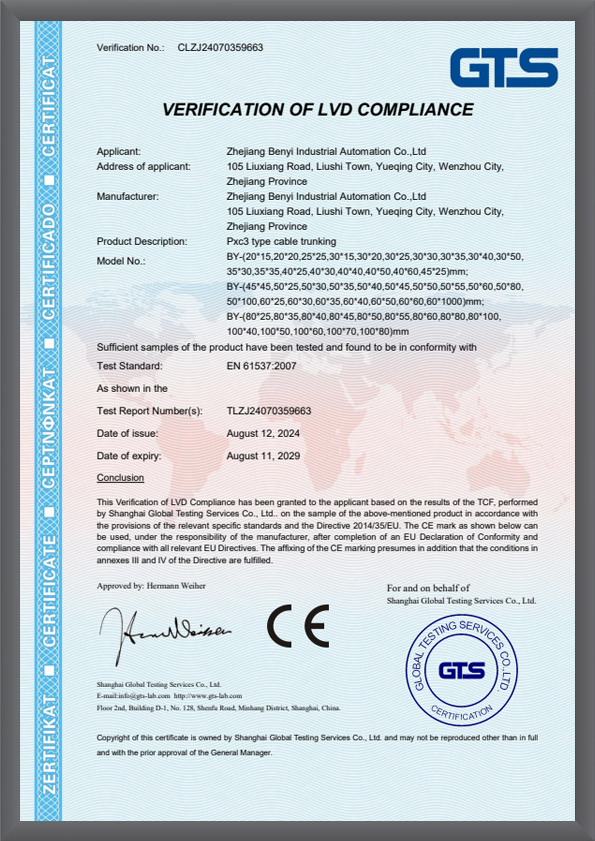

TLZJ24070359665

TLZJ24070359665 -

CLZJ24070359665

CLZJ24070359665 -

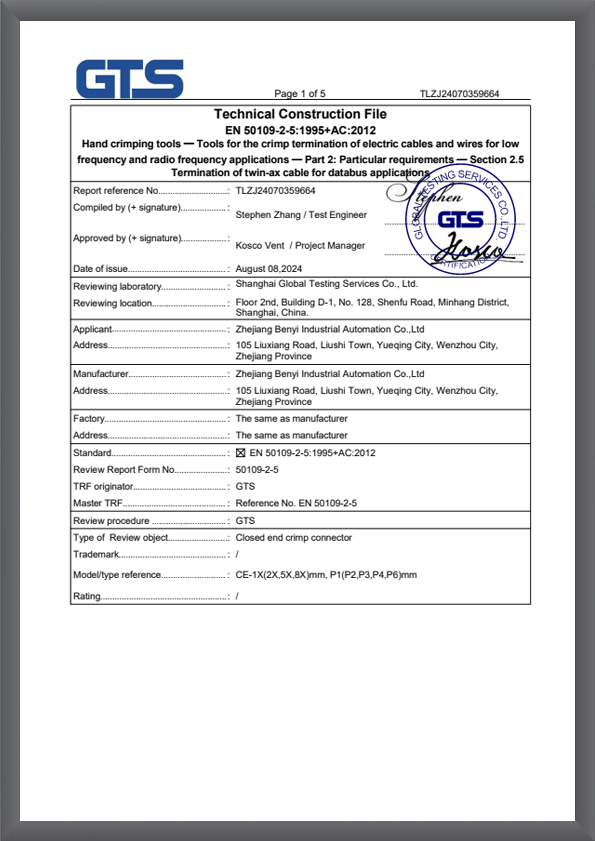

TLZJ24070359664

TLZJ24070359664 -

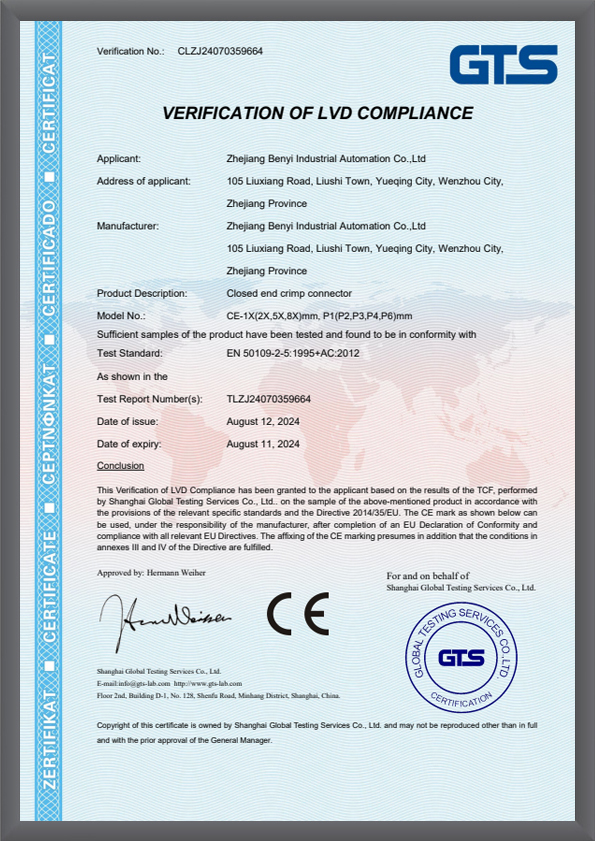

CLZJ24070359664

CLZJ24070359664 -

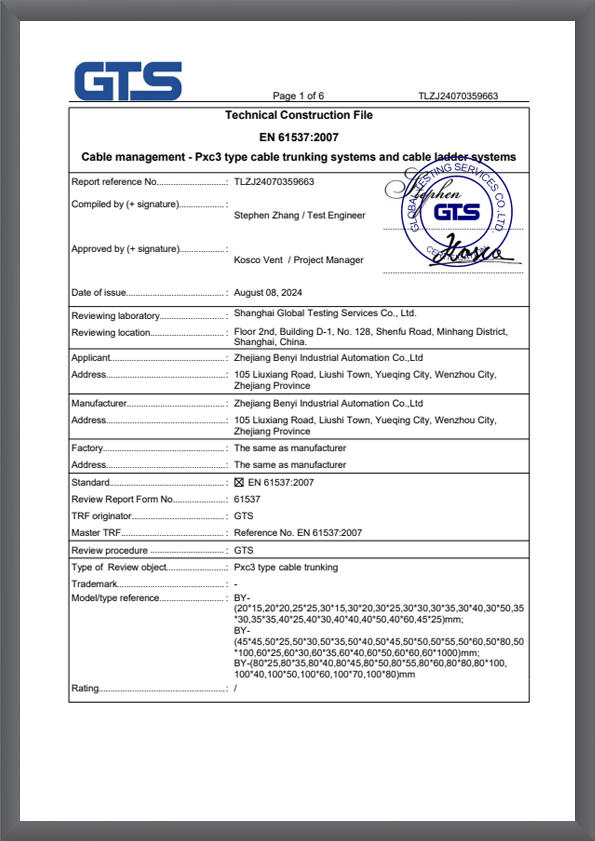

TLZJ24070359663

TLZJ24070359663 -

CLZJ24070359663

CLZJ24070359663

News

-

Industry News 2026-02-13

Copper terminals and lugs are common components in electrical distribution and wiring systems, serving both conductivity and mechanical connection pur...

View More -

Industry News 2026-02-06

Cold-pressed insulated terminals are widely used in electrical systems to provide secure and reliable wire connections. These terminals are manufactur...

View More -

Industry News 2026-01-30

2:1 heat shrink tubes are widely used in industrial and electronic applications due to their ability to provide electrical insulation, mechanical prot...

View More -

Industry News 2026-01-23

Brass cable glands are essential components in industrial electrical systems. They secure cables as they enter equipment or enclosures, providing stra...

View More

Contact us now

+86-15558905711

+86-15558905711 +86-15057372736

+86-15057372736 [email protected]

[email protected] 105 Liuxiang Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province, China

105 Liuxiang Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province, China

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语