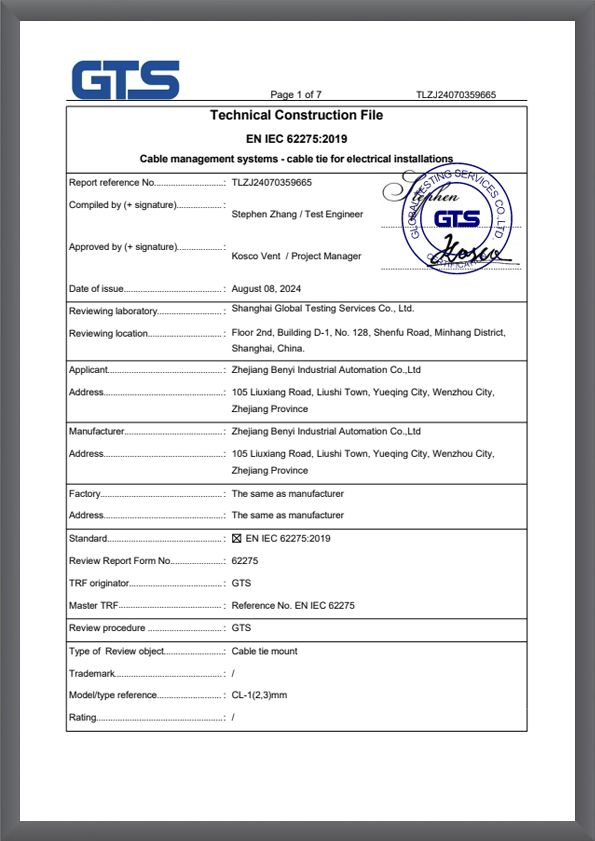

| Product information | |

| Feature | High Quality |

| Material | Nylon 66 |

| Sample | Offer free sample |

| Product Display | |||

| Model(L*W) | H(mm) | T(m m) | Screw Hole(mm) |

| 20*20 | 6.1 | 5 | 2.9 |

| 25*25 | 7.5 | 6.2 | 3.5 |

| 30*30 | 8.7 | 6.4 | 4.5 |

| 40*40 | 10.8 | 6.5 | / |

| Product information | |

| Feature | High Quality |

| Material | Nylon 66 |

| Sample | Offer free sample |

| Product Display | |||

| Model(L*W) | H(mm) | T(m m) | Screw Hole(mm) |

| 20*20 | 6.1 | 5 | 2.9 |

| 25*25 | 7.5 | 6.2 | 3.5 |

| 30*30 | 8.7 | 6.4 | 4.5 |

| 40*40 | 10.8 | 6.5 | / |

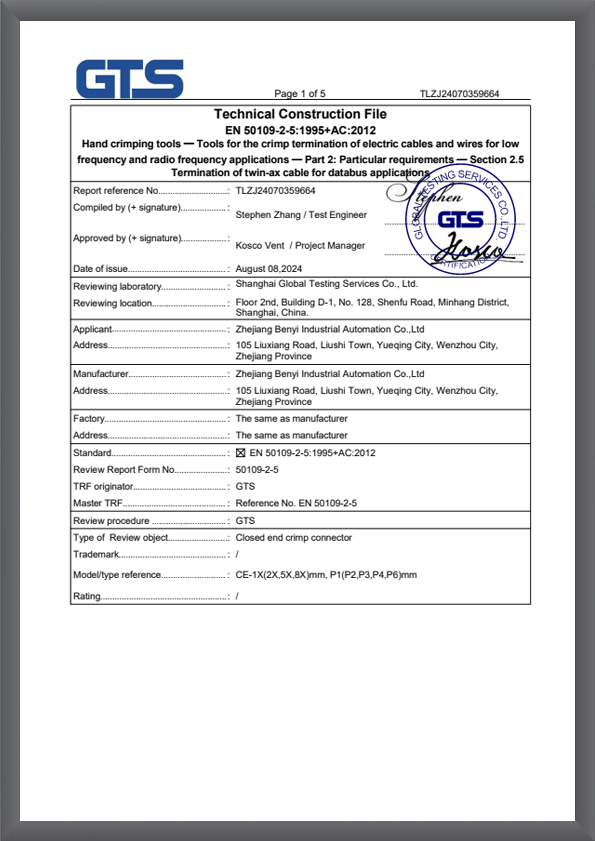

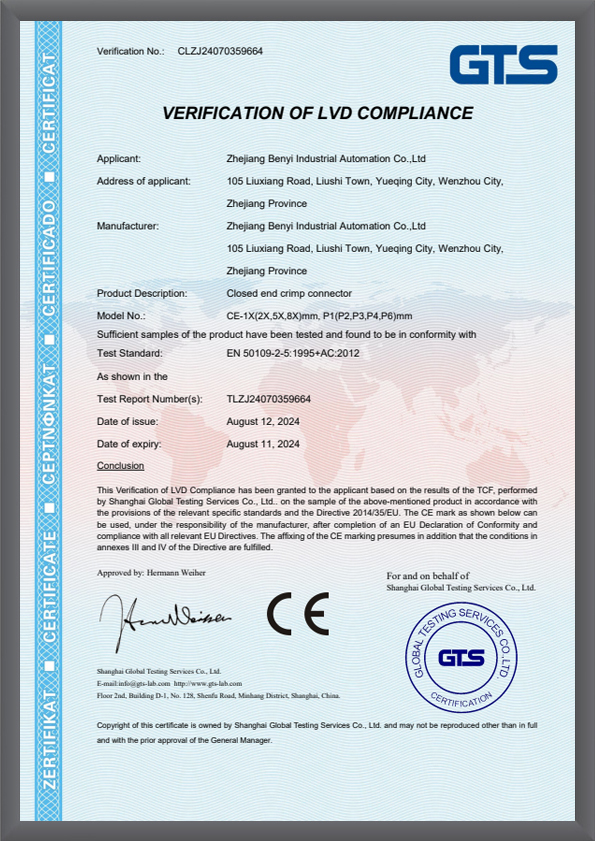

Color: White/Black

Material: PA66 Nylon

Purpose: Fix with screws, put the wires into the grooves, lock with cable ties, and cut off excess cable ties.

| Model Number | Number Of Packages | Pieces |

| HC-0(3MM) | 1000 | 100 |

| HC-0(4MM) | 1000 | 100 |

| HC-0(5MM) | 1000 | 100 |

| HC-1(3MM) | 1000 | 100 |

| HC-1(4MM) | 1000 | 100 |

| HC-1S(3MM) | 1000 | 100 |

| HC-2(4MM) | 500 | 50 |

| HC-2S(5MM) | 500 | 50 |

| HC-2(6MM) | 500 | 50 |

| HC-3(5MM) | 500 | 50 |

| HC-4(5MM) | 500 | 50 |

| HC-5(5MM) | 500 | 50 |

| HC-7 (5MM) | 500 | 20 |

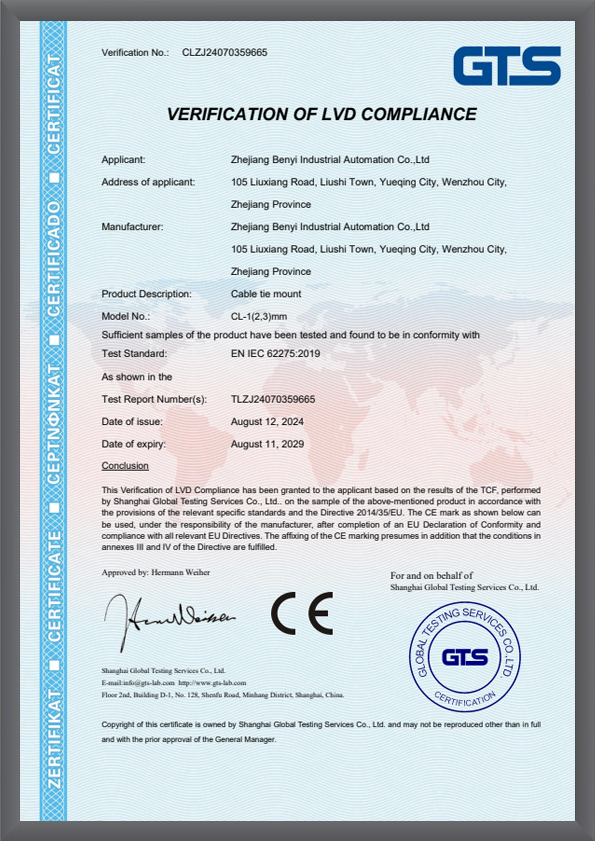

Cable Tie Mounts are small, robust devices designed to anchor cable ties to surfaces. They act as a base that helps secure cables, preventing them from becoming tangled or damaged. The mounts themselves can be fixed to various surfaces using adhesives, screws, or clips, depending on the design and the environment in which they will be used. They provide an easy solution for managing cables, wires, and hoses in both residential and industrial settings.

1. Types of Cable Tie Mounts

There are several types of Cable Tie Mounts available, each designed to serve specific installation needs:

Adhesive Cable Tie Mounts: These mounts have a self-adhesive backing that allows them to be easily installed without the need for screws or other tools. They are ideal for applications where drilling or puncturing the surface is not desirable. Adhesive mounts are typically used on smooth, clean surfaces such as walls, ceilings, or flat surfaces in electronic devices.

Screwable Cable Tie Mounts: These mounts feature holes for screws or bolts, allowing them to be securely fastened to surfaces like metal, wood, or plastic. Screwable mounts are ideal for applications requiring extra security or where the mount may be subjected to heavy loads or vibrations.

Push-in Cable Tie Mounts: Push-in mounts can be installed quickly by simply pushing them into pre-drilled holes. These are often used in situations where the installation needs to be rapid and efficient.

Clip-on Cable Tie Mounts: These mounts feature a clip mechanism that allows them to be snapped into place on various fixtures. They offer flexibility and convenience, making them perfect for temporary setups or areas where reinstallation may be necessary.

2. Applications of Cable Tie Mounts

Cable Tie Mounts find use in a wide range of applications across various industries:

Electrical Installations: In homes, offices, and industrial facilities, cable tie mounts are used to secure electrical wiring and cables. Properly mounted cables reduce the risk of electrical hazards and make future maintenance or upgrades easier.

Automotive Industry: Cable tie mounts are commonly used in vehicles to secure electrical cables and wiring systems. The mounts ensure that the cables remain in place, even under the harsh conditions of heat, moisture, and vibrations.

Telecommunications: In telecom infrastructure, cable tie mounts are essential for organizing and securing the numerous cables that run between equipment and along network lines.

HVAC Systems: In heating, ventilation, and air conditioning systems, cable tie mounts are used to manage the electrical wiring and sensors that run throughout the system.

Medical Devices: In medical equipment, where reliability and cleanliness are paramount, cable tie mounts help ensure that electrical wiring is organized, protected, and easily accessible for maintenance.

3. Installation and Usage

The installation of cable tie mounts is straightforward:

For Adhesive Mounts: Clean the surface where the mount will be applied, remove the backing from the adhesive, and press the mount firmly into place.

For Screwable Mounts: Align the mount with the desired surface, drill holes if necessary, and secure the mount with screws or bolts.

For Push-in and Clip-on Mounts: Simply push the mount into a pre-drilled hole or snap it onto a fixture, ensuring it is securely fastened.

Whether for home use or industrial applications, investing in high-quality cable tie mounts can significantly enhance the lifespan of cables, improve the safety of installations, and contribute to a cleaner, more organized space.

Copper terminals and lugs are common components in electrical distribution and wiring systems, serving both conductivity and mechanical connection pur...

View MoreCold-pressed insulated terminals are widely used in electrical systems to provide secure and reliable wire connections. These terminals are manufactur...

View More2:1 heat shrink tubes are widely used in industrial and electronic applications due to their ability to provide electrical insulation, mechanical prot...

View MoreBrass cable glands are essential components in industrial electrical systems. They secure cables as they enter equipment or enclosures, providing stra...

View More