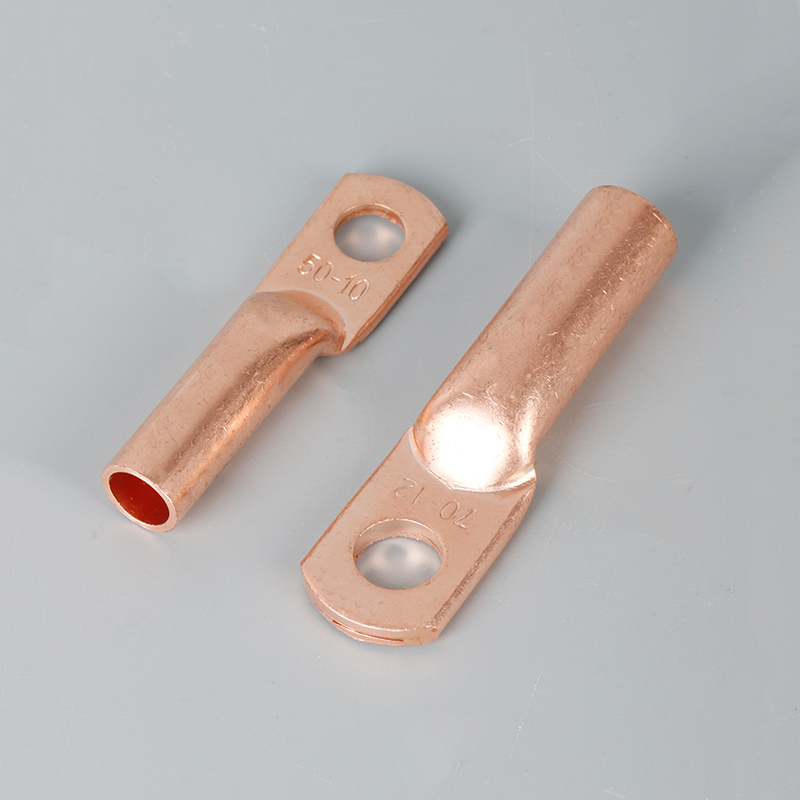

Copper terminals are essential components used in various industries for electrical and electronic connections. These terminals are designed to provide a secure and reliable means of connecting wires or cables to electrical systems, ensuring the efficient transfer of electrical signals and power.

1. Material and Composition

Copper terminals are primarily made from copper or copper alloys, which are selected for their excellent electrical conductivity and resistance to corrosion. Copper is one of the most conductive metals, second only to silver, and can transmit electricity with minimal resistance. This makes copper terminals ideal for use in a wide range of electrical applications. The copper material is often coated with a thin layer of tin or other corrosion-resistant materials to enhance its longevity and prevent oxidation, which could otherwise impair the connection’s performance.

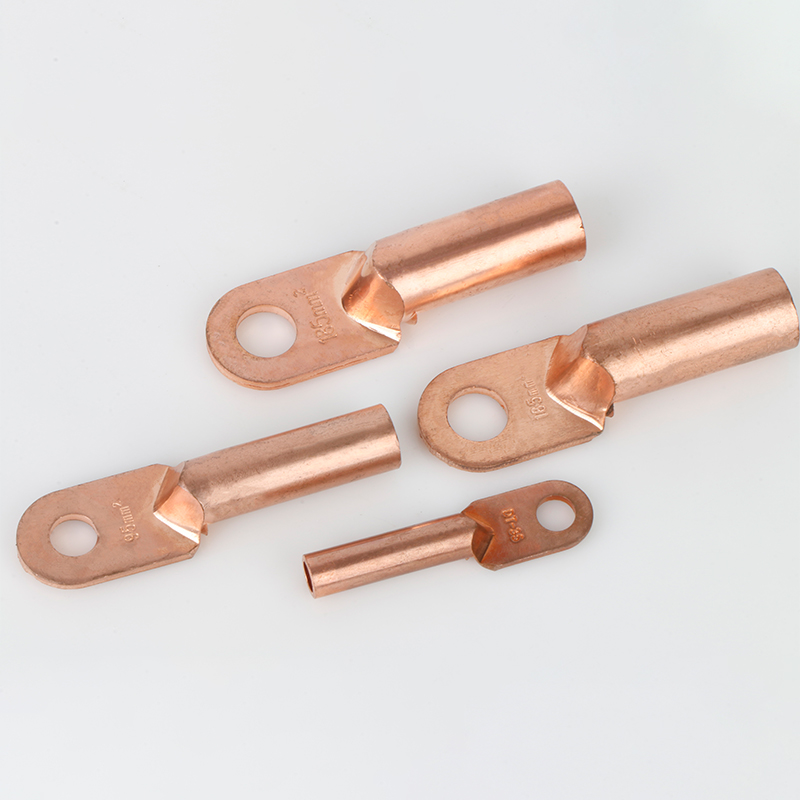

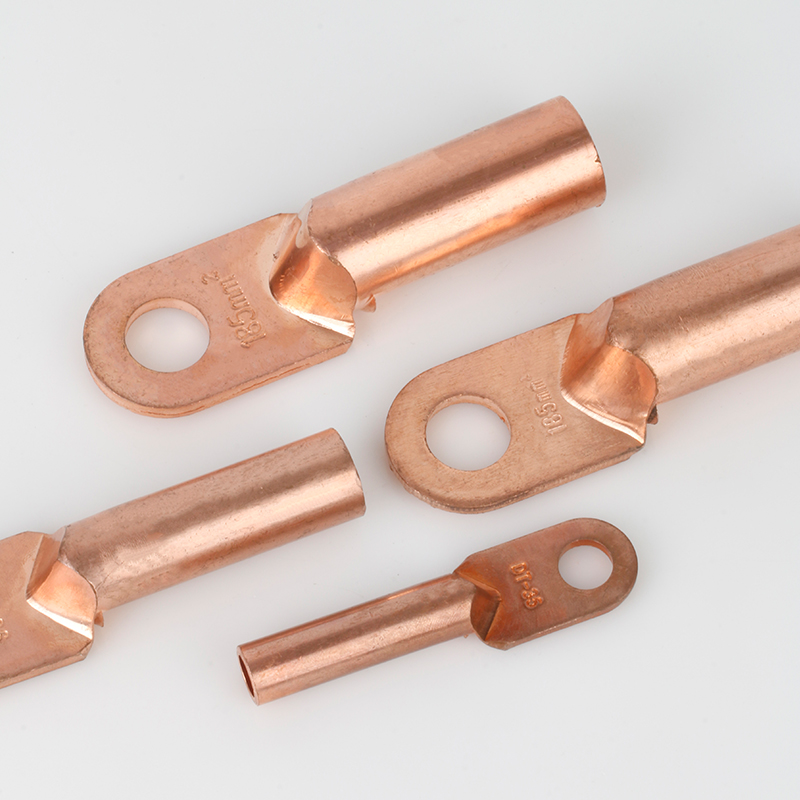

2. Types of Copper Terminals

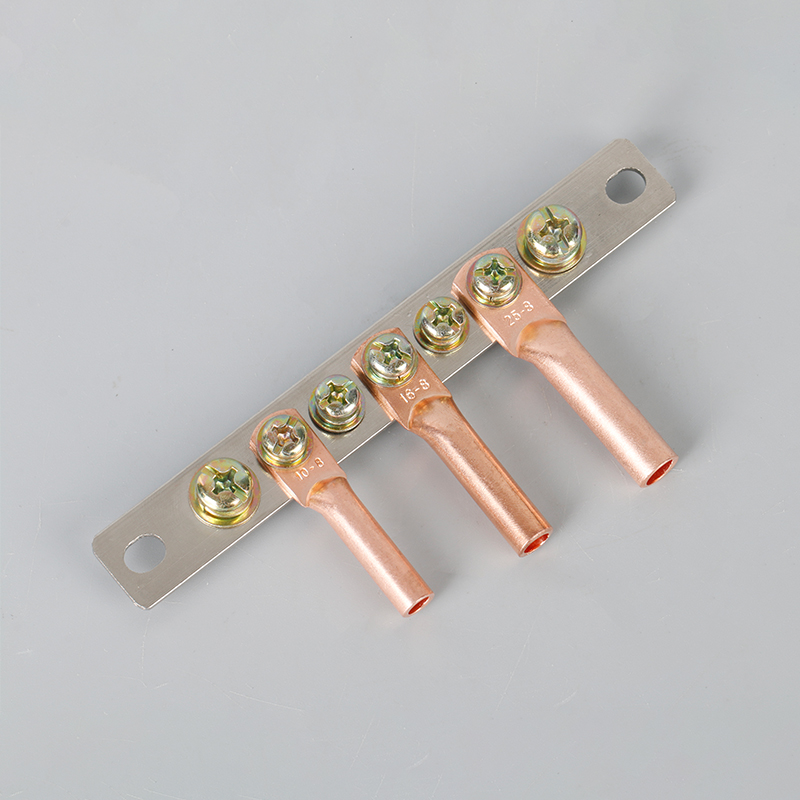

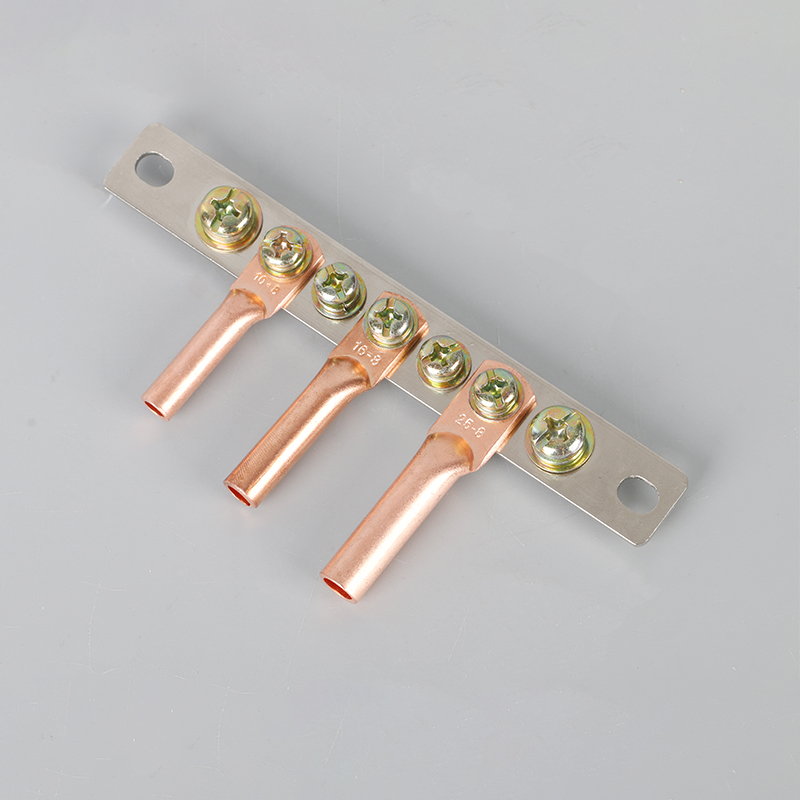

Copper terminals come in a variety of forms, each designed for specific applications and requirements. The most common types include:

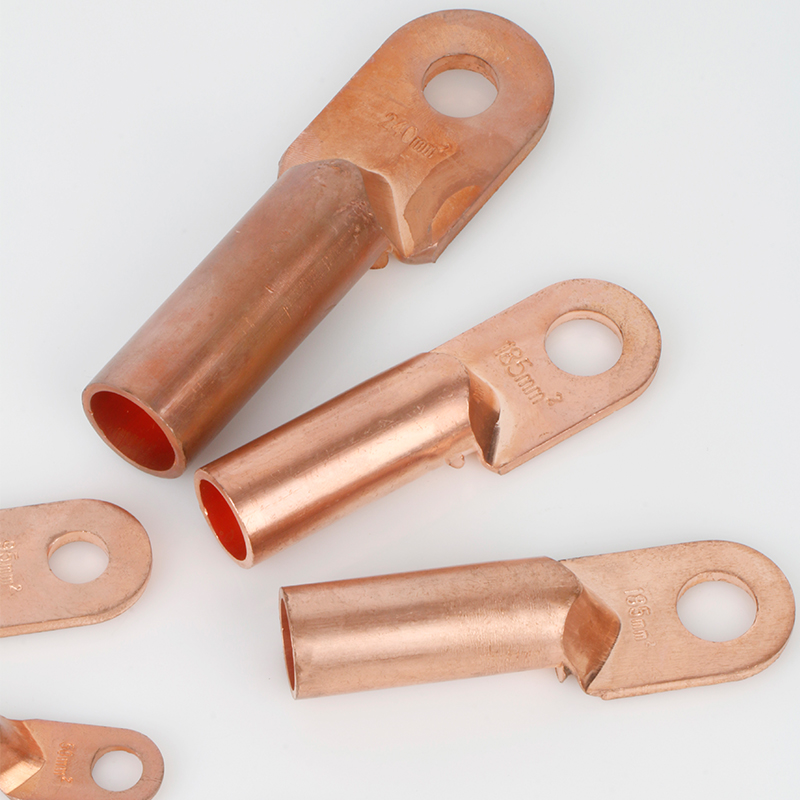

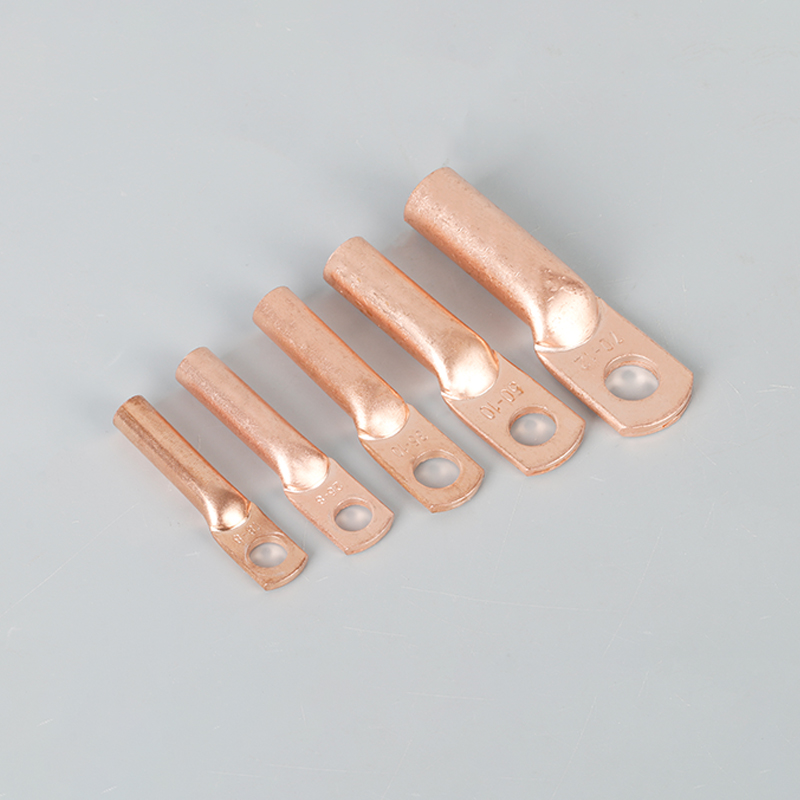

Ring Terminals: These terminals have a circular ring shape at the end, which allows them to be attached to a bolt or screw. The ring terminal is commonly used for high-current applications, as it provides a secure and low-resistance connection.

Spade Terminals: With a fork-like design, spade terminals are used for quick connect and disconnect applications. They are ideal for use in electrical panels and automotive systems.

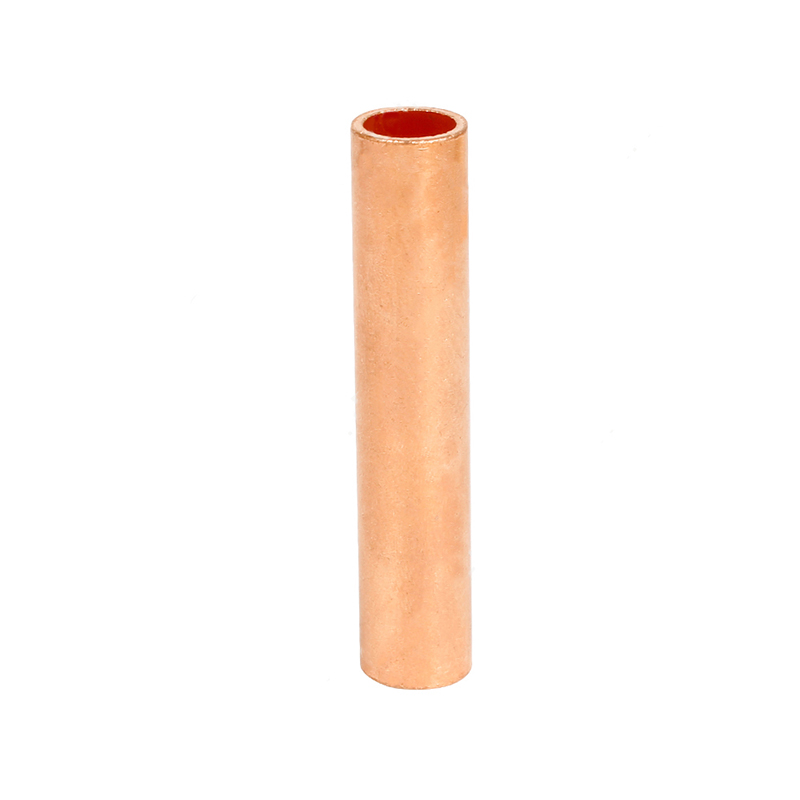

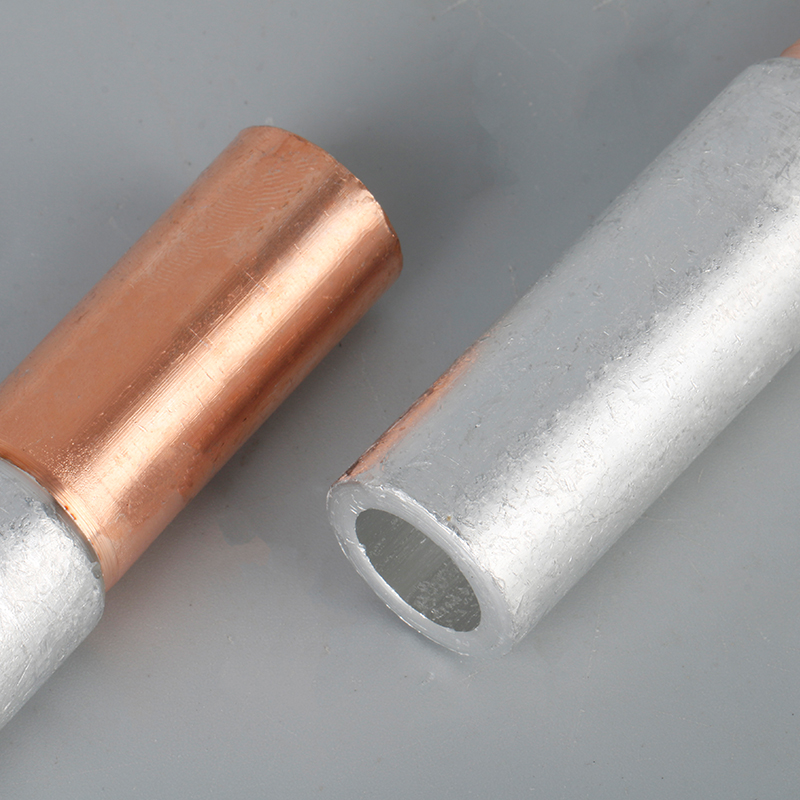

Butt Connectors: These are cylindrical terminals used to join two wires together. They are often used in wire splicing applications where a permanent or semi-permanent connection is required.

Flag Terminals: Flag terminals feature a flat, flag-like design that is used for connecting terminals in tight spaces or areas with limited access.

Push-On Terminals: These terminals are designed for quick and easy connection and disconnection. They are typically used in applications where frequent maintenance or replacements are needed.

Each type of copper terminal is chosen based on the needs of the specific electrical system, with considerations for factors such as current load, space limitations, and ease of installation.

3. Manufacturing Process

The production of copper terminals involves several steps to ensure high-quality products that meet industry standards. The typical process includes:

Material Selection: High-purity copper is selected for the terminals to ensure maximum conductivity and durability.

Stamping or Molding: Copper sheets or rods are stamped or molded into the desired terminal shape. This process involves precision tooling to create consistent shapes and sizes.

Tinning or Coating: Copper terminals are often coated with a layer of tin to prevent oxidation and improve their corrosion resistance. The tinning process is done through electroplating or hot-dipping.

Crimping or Soldering: Depending on the type of terminal, wires are attached to the copper terminal using crimping or soldering methods. Crimping involves using a special tool to compress the terminal around the wire, ensuring a strong electrical connection.

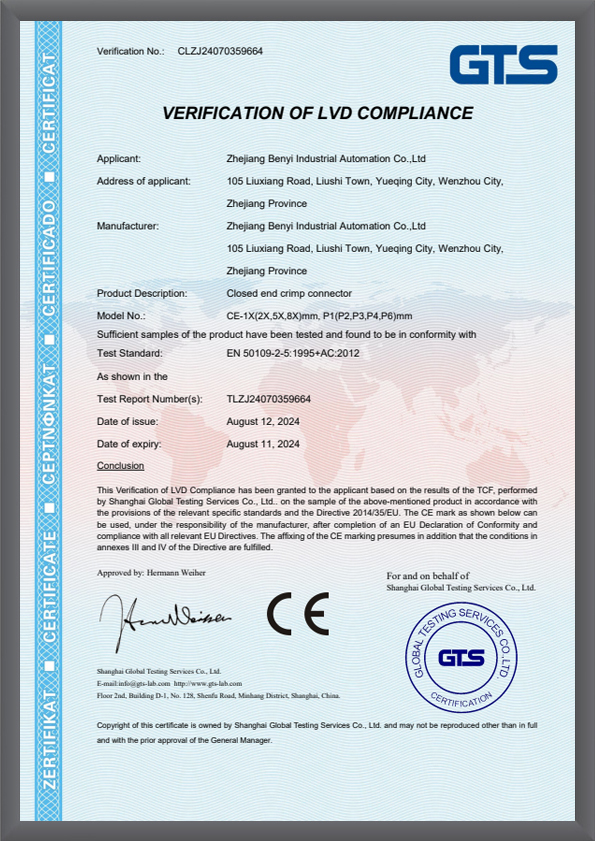

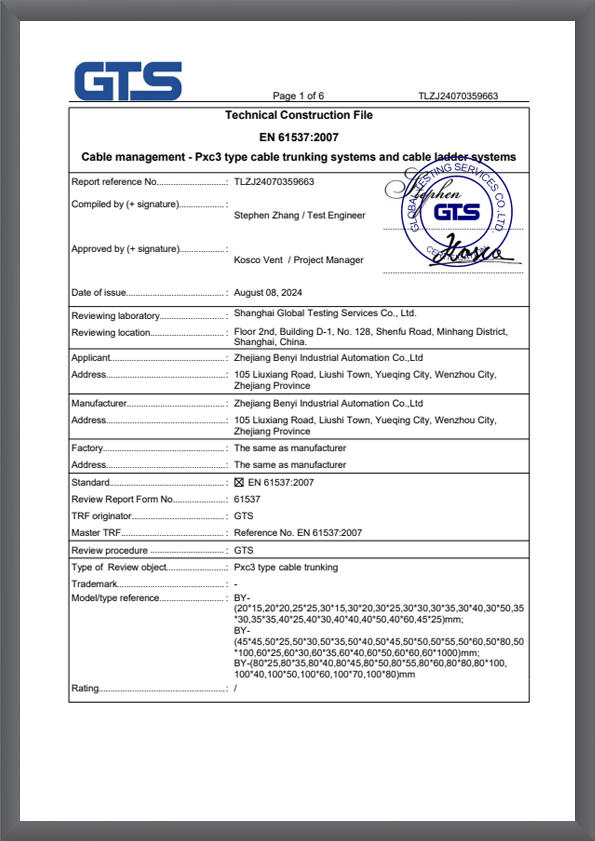

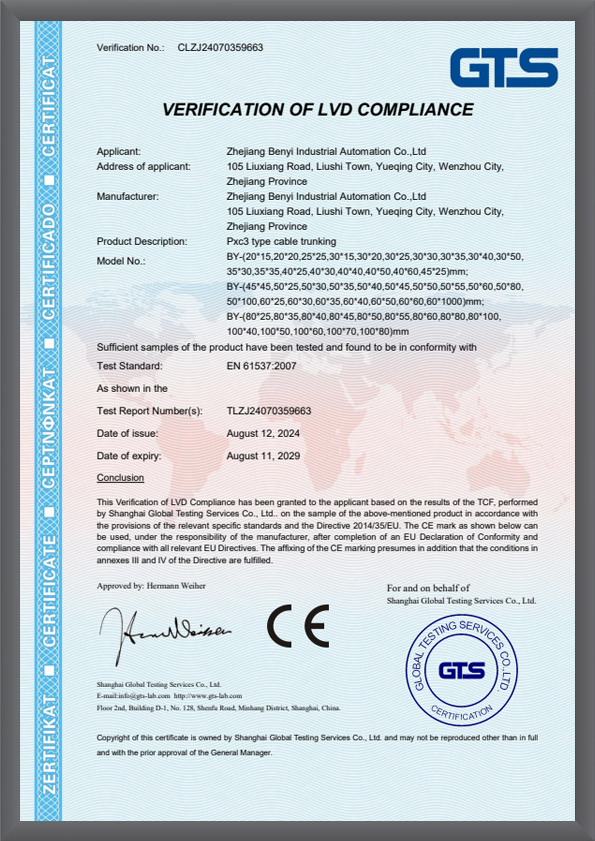

Inspection and Testing: After production, each copper terminal undergoes rigorous testing to ensure its quality, performance, and safety. This may include tests for electrical conductivity, corrosion resistance, and physical integrity.

By choosing the right type of copper terminal and ensuring proper installation, industries can maintain the efficiency and reliability of their electrical systems for years to come. As technology continues to evolve, copper terminals will remain a crucial element in ensuring the smooth operation of modern electrical infrastructure.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语