Web Menu

Product Search

Exit Menu

Corrugated Conduit Gland PA in Modern Installations

The Corrugated Conduit Gland PA is drawing renewed interest across manufacturing plants, automation workshops, and infrastructure projects as engineers and contractors increasingly prioritize durable and flexible cable protection. With growing demands on safety, reliability, and adaptability of wiring systems, this PA‑based gland is proving a practical component for contemporary installations — particularly where complexity, environmental exposure, or frequent maintenance are involved.

Why It’s Gaining Attention

Recent shifts in industry practices — such as automation upgrades, rising compliance with ingress‑protection requirements, and increased use of flexible conduit systems — spotlight the value of cable glands that combine sealing, strain relief, and flexibility. Cable glands are no longer viewed as mere accessories, but as essential safeguards to prevent moisture, dust, chemical ingress, mechanical stress, and vibration-induced cable damage in demanding environments.

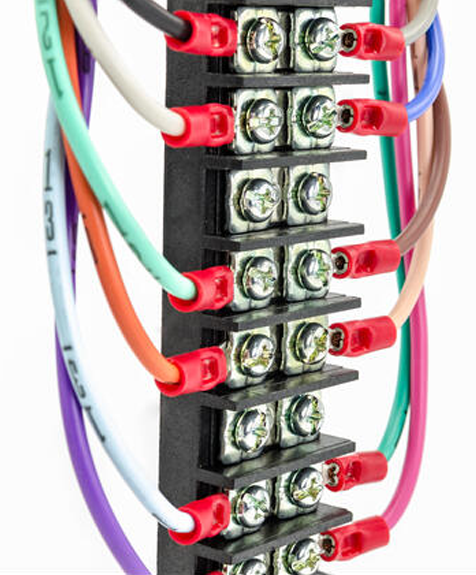

As cable density and complexity increase — for example, in control cabinets, robotic cells, or data‑handling systems — wiring must navigate tighter conduits, bends, and enclosure entries. Corrugated conduit systems paired with PA glands meet these challenges by allowing flexibility while maintaining tight seals and secure cable routing.

Key Technical and Environmental Advantages

- Secure Sealing & Strain Relief: The PA gland ensures a snug fit between conduit and cable, blocking dust, moisture, or chemical intrusion. In vibration‑prone settings (e.g. manufacturing floors, automotive assembly lines), this prevents unintended cable movement or loosening.

- Material Resilience: PA material resists abrasion, many common industrial chemicals, and moderate temperature and humidity swings — vital for plants, outdoor installations, or mixed‑environment use.

- Flexible Conduit Compatibility: Unlike rigid conduits, corrugated conduit + PA gland combinations allow easier routing through tight spaces, around corners, or along complex cable paths, simplifying wiring layout and maintenance.

- Adaptability for Diverse Use Cases: From automation control cabinets to lighting systems, automotive harnesses to telecom enclosures — the design works across sectors, reflecting growing cross‑industry adoption.

Considerations & Best Practices

While Corrugated Conduit Gland PA offers benefits, proper specification and installation are important to ensure performance:

- Correct Sizing: The gland must match the outer diameter of the corrugated conduit and the cable bundle to guarantee a tight seal. A mismatch may leave gaps, compromising sealing or strain relief.

- Sealing and Environmental Context: In environments with dust, moisture, chemicals, or vibration, extra sealing rings or gaskets may be needed to ensure long-term protection.

- Periodic Inspection: Especially in harsh industrial or outdoor settings, periodic checks for wear, loosening, or degradation help maintain system integrity and prevent faults.

- Routing Planning: When installing in tight or complex layouts, conduit bends and gland placements should be planned to avoid sharp angles or undue stress on cables.

What This Means for Project Planning

As industries evolve — with increased automation, more complex wiring setups, and stricter environmental and safety standards — components like Corrugated Conduit Gland PA are gaining importance beyond simple conduit termination. Their combination of flexibility, protection, and reliability supports modern requirements for wiring systems that need to be both adaptable and robust.

For engineers, maintenance teams, and wiring planners, embracing PA‑gland + corrugated conduit solutions can offer a balanced approach: reducing mechanical risk, simplifying installation, and improving long-term durability across variable environments and use cases.

In conclusion, the Corrugated Conduit Gland PA stands out as a pragmatic, versatile component for contemporary wiring and conduit systems — offering balance between flexibility and protection, and addressing modern demands for reliability in complex installations.

News categories

Exhibition Information

Related Products

+86-15558905711

+86-15558905711 +86-15057372736

+86-15057372736 [email protected]

[email protected] 105 Liuxiang Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province, China

105 Liuxiang Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province, China

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语