| Model | Wire rang (mm2) | Bolt hole (mm) | Thickness(mm) | Pcs/bag |

| SV1.25-3 | 0.5-1.5 | 3.2 | 0.5 | 1000 |

| SV1.25-4 | 0.5-1.5 | 4.2 | 0.5 | 1000 |

| SV2-3 | 1.5-2.5 | 3.2 | 0.5 | 1000 |

| SV2-4 | 1.5-2.5 | 4.2 | 0.5 | 1000 |

| SV1.25-3 | 0.5-1.5 | 3.2 | 0.6 | 1000 |

| SV1.25-4 | 0.5-1.5 | 4.2 | 0.6 | 1000 |

| SV1.25-5 | 0.5-1.5 | 5.2 | 0.6 | 1000 |

| SV1.25-6 | 0.5-1.5 | 6.2 | 0.6 | 1000 |

| SV2-3 | 1.5-2.5 | 3.2 | 0.6 | 1000 |

| SV2-4 | 1.5-2.5 | 4.2 | 0.6 | 1000 |

| SV2-5 | 1.5-2.5 | 5.2 | 0.6 | 1000 |

| SV2-6 | 1.5-2.5 | 6.2 | 0.6 | 1000 |

| SV3.5-4 | 2.5-4 | 4.2 | 0.8 | 500 |

| SV3.5-5 | 2.5-4 | 5.2 | 0.8 | 500 |

| SV3.5-6 | 2.5-4 | 6.2 | 0.8 | 500 |

| SV5.5-4 | 4-6 | 4.2 | 0.8 | 500 |

| SV5.5-5 | 4-6 | 5.2 | 0.8 | 500 |

| SV5.5-6 | 4-6 | 6.2 | 0.8 | 500 |

| SV5.5-8 | 4-6 | 8.2 | 0.8 | 500 |

Web Menu

Product Search

Exit Menu

Insulated Electrical Terminal Manufacturer

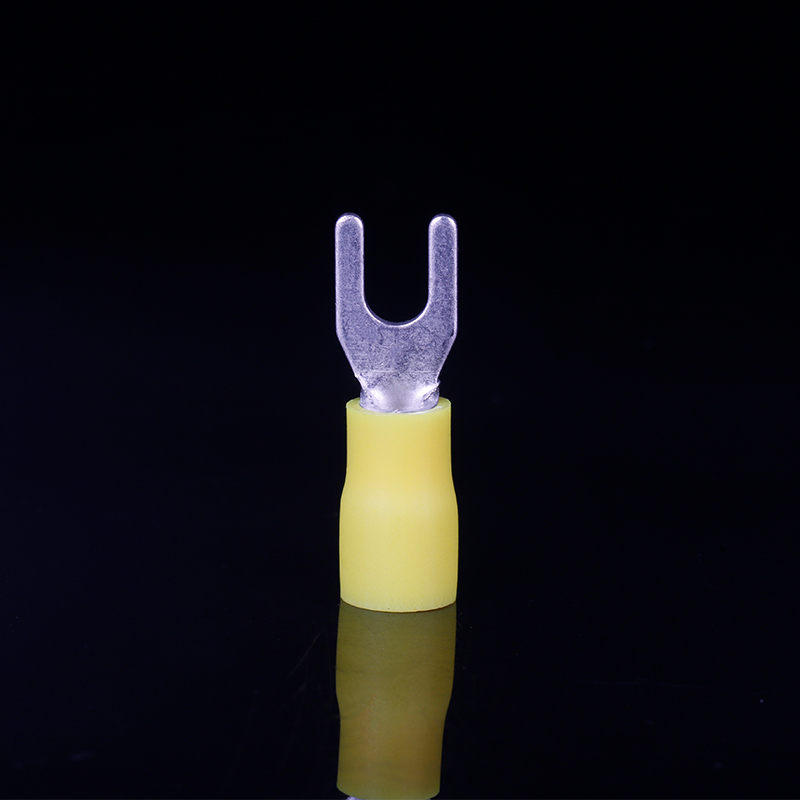

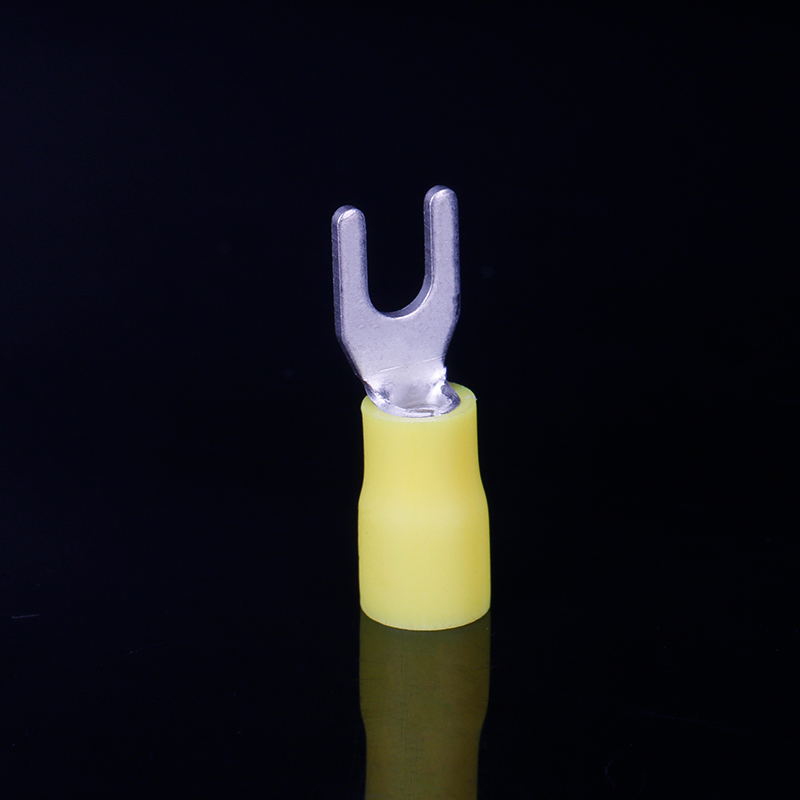

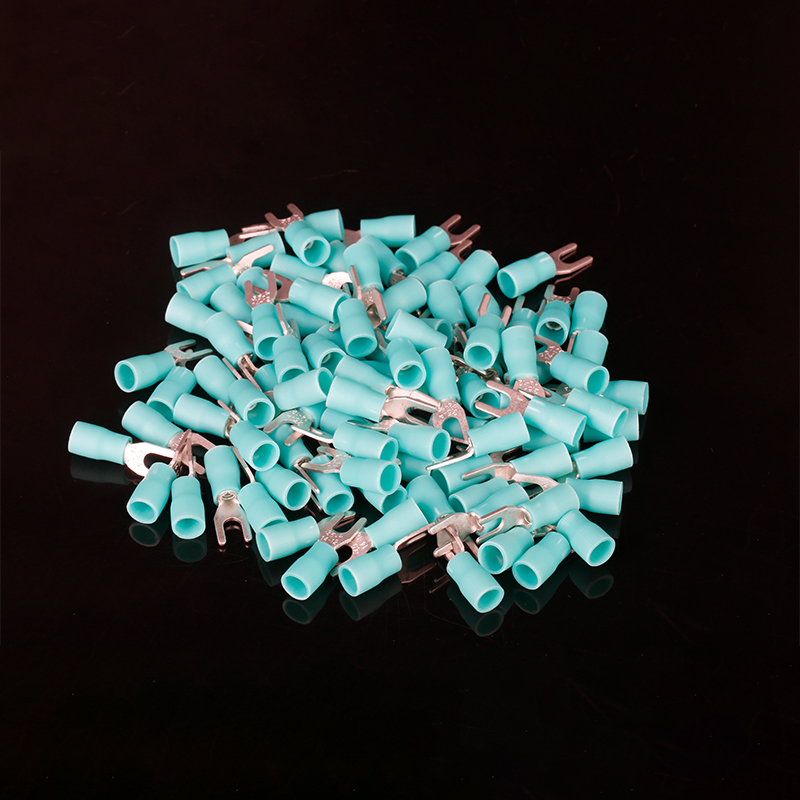

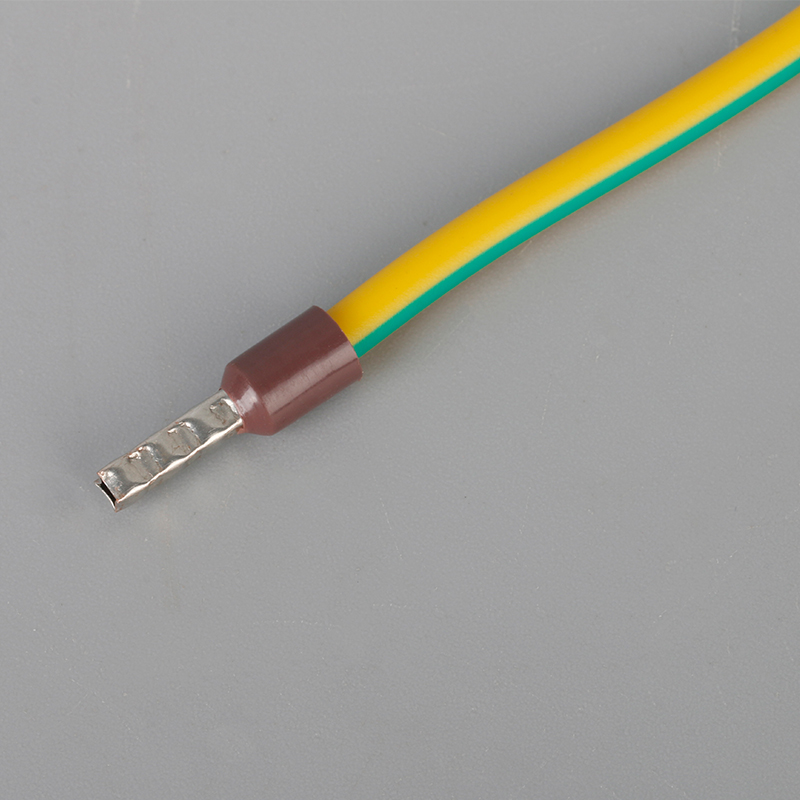

SV Fork Insulated Terminal

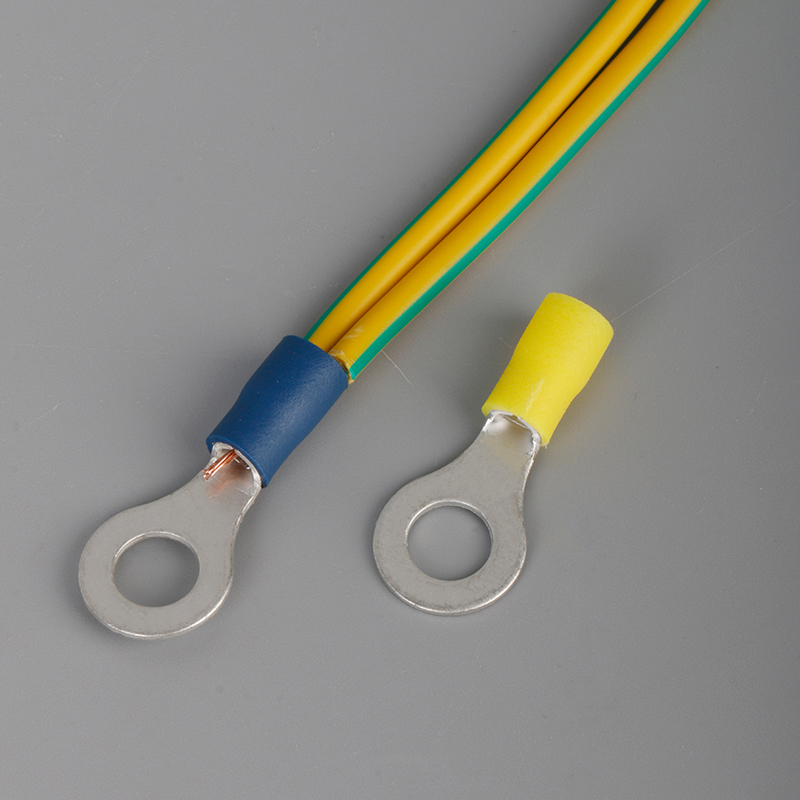

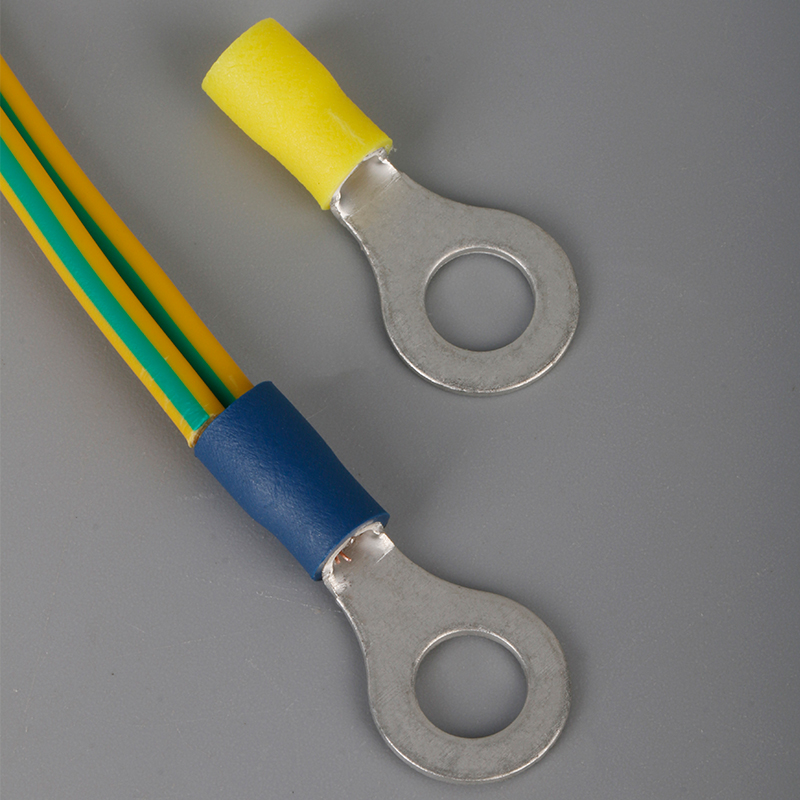

RV Ring Insulated Terminal

| Model | USA screW | Screw dia (d2.mm) | Dmen sion (mm) | Color | ||||

| B | L | F | H | Dφ | ||||

| RV1.25-3.2 | #4 | 3.2 | 5.7 | 17.8 | 4.95 | 10 | 4.3 | Red |

| RV1.25-3.7S | #6 | 3.7 | 5.7 | 17.8 | 4.95 | |||

| RV1.25-3.7M | #6 | 3.7 | 6.6 | 20.1 | 6.3 | |||

| RV1.25-3.7L | #6 | 3.7 | 8 | 21.5 | 7 | |||

| RV1.25-4S | #8 | 4.3 | 6.6 | 20.1 | 6.3 | |||

| RV1.25-4L | #8 | 4.3 | 8 | 21.5 | 7 | |||

| RV1.25-5 | #10 | 5.3 | 8 | 21.5 | 7 | |||

| RV1.25-5L | #10 | 5.3 | 9.5 | 23 | 8.5 | |||

| RV1.25-6S | 1-4 | 6.4 | 31.6 | 23 | 8.5 | |||

| RV1.25-6 | 1-4 | 6.4 | 9.8 | 27.5 | 11.1 | |||

| RV1.25-8 | 5-16 | 8.4 | 11.6 | 27.5 | 11.1 | |||

| RV 1.25-10 | 3-8 | 10.5 | 13.6 | 31.6 | 13.9 | |||

| RV 1.25-12 | 1-2 | 13 | 19.2 | 35.4 | 16 | |||

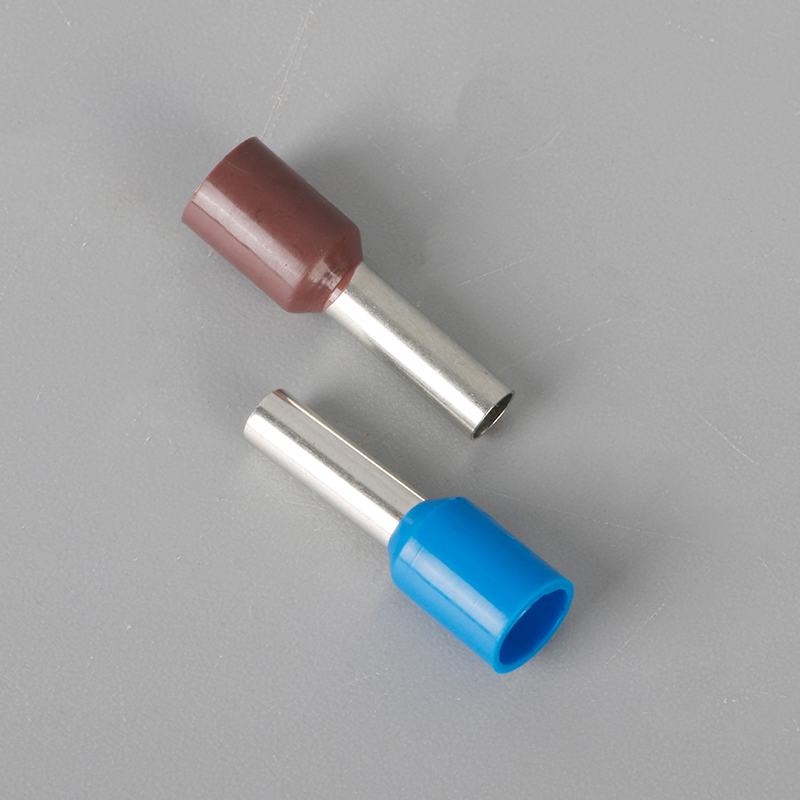

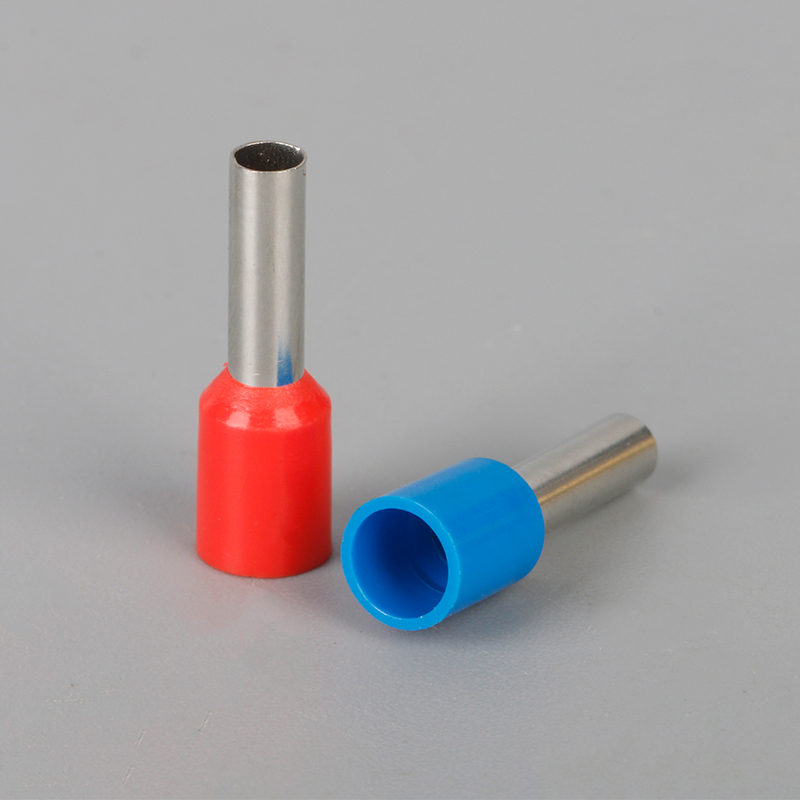

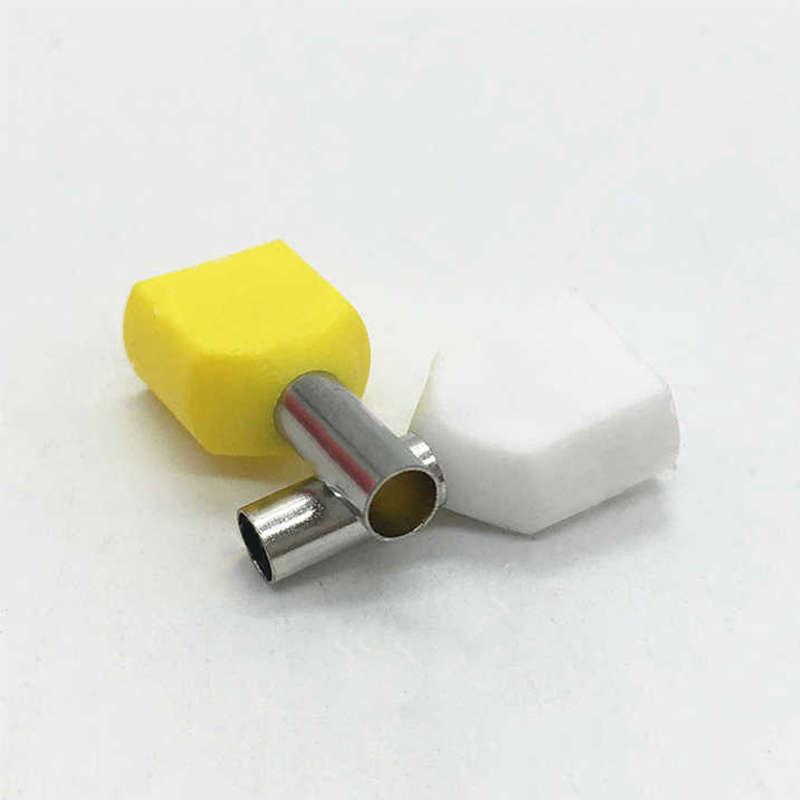

VE Insulated Ferrule Terminal

| Model | Dimension(mm) | Wire range (mm2) | |||||

| F | L | W | Dφ | Cφ | A.W.G | ||

| E0506 | 6 | 12 | 2.5 | 1.3 | 1 | #22 | 0.5 |

| E0508 | 8 | 14 | |||||

| E 0510 | 10 | 16 | |||||

| E 0512 | 12 | 18 | |||||

| E7506 | 6 | 12.4 | 2.8 | 1.5 | 1.2 | #20 | 0.75 |

| E7508 | 8 | 14.6 | |||||

| E7510 | 10 | 16.4 | |||||

| E7512 | 12 | 18.4 | |||||

| E 1006 | 6 | 12.4 | 3 | 1.7 | 1.4 | #18 | 1 |

| E 1008 | 8 | 14.6 | |||||

| E 1010 | 10 | 16.4 | |||||

| E 1012 | 12 | 18.4 | |||||

| E1508 | 8 | 14.6 | 3.5 | 2 | 1.7 | #16 | 1.5 |

| E 1510 | 10 | 16.4 | |||||

| E 1512 | 12 | 18.4 | |||||

| E 1518 | 18 | 24.4 | |||||

| (E 2508 | 8 | 15.2 | 4 | 2.6 | 2.3 | #14 | 2.5 |

| E 2510 | 10 | 17.2 | |||||

| E 2512 | 12 | 19.2 | |||||

| E 2518 | 18 | 25.2 | |||||

| E4009 | 9 | 16.5 | 4.4 | 3.2 | 2.8 | #12 | 4 |

| E4012 | 12 | 19.5 | |||||

| E4018 | 18 | 25.5 | |||||

| E 6010 | 10 | 18 | 6.3 | 3.9 | 3.5 | #10 | 6 |

| E 6012 | 12 | 20 | |||||

| E 6018 | 18 | 26 | |||||

| E 10-12 | 12 | 21.5 | 7.6 | 4.9 | 4.5 | #7 | 10 |

| E 10-18 | 18 | 27.5 | |||||

| E 16-12 | 12 | 22.2 | 8.8 | 6.2 | 5.8 | #5 | 16 |

| E 16-18 | 18 | 28.2 | |||||

| E 25-16 | 16 | 29 | 11.2 | 7.9 | 7.5 | #4 | 25 |

| E 25-22 | 22 | 35 | |||||

| E35-16 | 16 | 30 | 12.7 | 8.7 | 8.3 | #2 | 35 |

| E 35-25 | 25 | 39 | |||||

| E50-20 | 20 | 36 | 15.3 | 10.9 | 10.3 | #1 | 50 |

| E50-25 | 25 | 41 | |||||

TE Insulated Ferrule Terminal

| Material | copper/brass |

| Color | Red, Yellow, Green, Black.Blue |

| Features | High quality and competitive price |

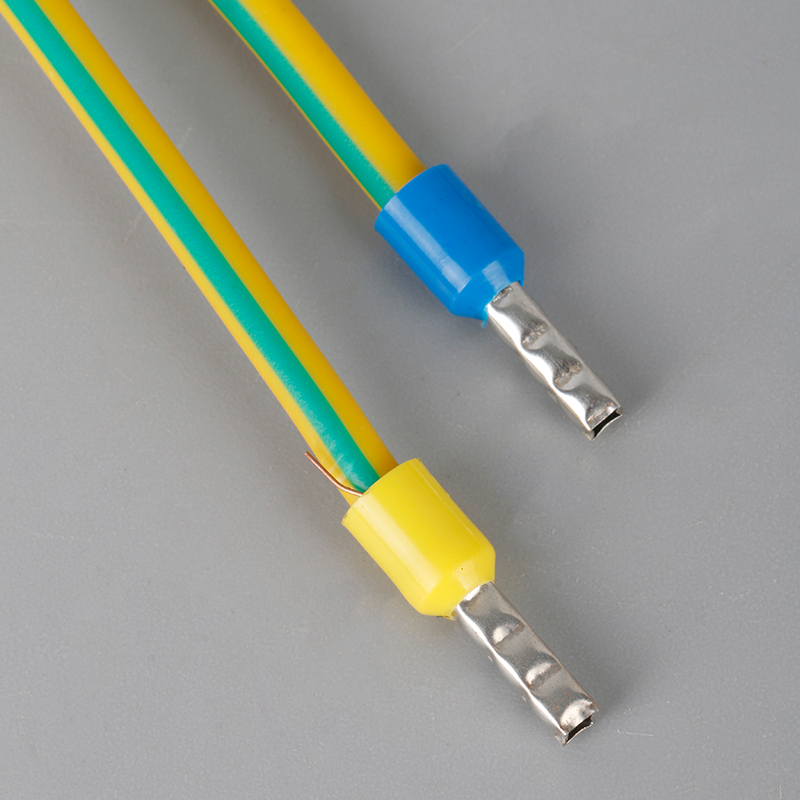

PTV Insulated Pin Terminal

| Material | Brass, Plastic |

| Wire Size | Red:0.5.1.5mm2 Blue:1.5~2.5mm2 Yellow:4-6mm2 |

| Sample | Free |

MPD Bullet Type Insulated Mal Terminal

(1)High quality, competitive price.

(2)Customizable some different copper connectors or.

(3)Flexible and conductive.

(4) Made of high-purity copper.

(5)Offerfree sample.

| Cable Number | Cable Selection | A.W.G | Imax Current | Thickness |

| 1.25 | 0.5~1.5mm2 | 22~16 | 19A | 0.7mm |

| 2 | 1.5~2.5mm2 | 16~14 | 27A | 0.8mm |

| 3.5 | 2.5~4mm2 | 14~12 | 37A | 1.0mm |

| 5 | 4~6mm2 | 12~10 | 48A | 1.0mm |

| 8 | 6~10mm2 | 8 | 62A | 1.2mm |

FDD Insulated Femal Terminal

| Model | Name tab(mm) |

Material thickness | Size | Explain | ||||

| B | Dφ | dφ | L | H | ||||

| FDD 1.25-110(5) | 0.5x2.8 | 0.3 | 3.8 | 3.8 | 1.7 | 19 | 10 | Lead section:0.5~1.5mm2 (A. W.G 22~16) Material: Brass Imax:10A |

| FDD 1.25-110(8) | 0.8x2.8 | 0.3 | 3.8 | 3.8 | 1.7 | 19 | 10 | |

| FDD 1.25-187(5) | 0.5x4.75 | 0.35 | 5.6 | 3.8 | 1.7 | 19 | 10 | |

| FDD 1.25-187(8) | 0.8X4.75 | 0.35 | 5.6 | 3.8 | 1.7 | 19 | 10 | |

| FDD 1.25-2015 | 0.5X5.2 | 0.35 | 6.5 | 3.8 | 1.7 | 19 | 10 | |

| FDD 1.25-250 | 0.8X6.35 | 0.4 | 7.4 | 3.8 | 2.3 | 19 | 10 | |

| FDD 2-110(5) | 0.5X2.8 | 0.3 | 3.8 | 4.3 | 2.3 | 19 | 10 | Lead section:1.5~2. 5mm2 (A.W.G 16~14) Material: Brass Imax:15A |

| FDD 2-110(8) | 0.8X2.8 | 0.3 | 3.8 | 4.3 | 2.3 | 19 | 10 | |

| FDD 2-187(5) | 0.5X4.75 | 0.35 | 5.6 | 4.3 | 2.3 | 19 | 10 | |

| FDD 2-187(8) | 0.8X4.75 | 0.35 | 5.6 | 4.3 | 2.3 | 19 | 10 | |

| FDD 2-205 | 0.5X5.2 | 0.35 | 6.5 | 4.3 | 2.3 | 19 | 10 | |

| FDD 2-250 | 0.8X6.35 | 0.4 | 74 | 4.3 | 2.3 | 20 | 10 | |

| FDD 2-312 | 0.8X8.0 | 0.4 | 9 | 4.3 | 2.3 | 23 | 10 | |

| FDD 5.5-127 | 0.5X4.75 | 0.4 | 5.6 | 5.7 | 3.4 | 22 | 12.5 | Lead section:4~ 6nm2 (A. W.G 12~10) Material: Brass Imax:24A |

| FDD 5.5-250 | 0.8X6.35 | 0.4 | 7.4 | 5.7 | 3.4 | 25 | 13 | |

| FDD 5.5-375 | 1.2X9.4 | 0.5 | 10.9 | 5.7 | 3.4 | 29.6 | 13 | |

MDD Insulated Mal Terminal

| Model | Name tab(mm) |

Material thickness | Size | Explain | ||||

| B | Dφ | dφ | L | H | ||||

| MDD 1.25-110(5) | 0.5x2.8 | 0.5 | 2.8 | 1.7 | 4.3 | 17.7 | 10 | Lead section:0.5~1.5mm2 (A. W.G 22~16) Material: Brass Imax:10A |

| MDD 1.25-110(8) | 0.8x2.8 | 0.8 | 2.8 | 1.7 | 4.3 | 17.7 | 10 | |

| MDD 1.25-187(5) | 0.5x4.75 | 0.5 | 4.75 | 1.7 | 4.3 | 20 | 10 | |

| MDD 1.25-187(8) | 0.8x4.75 | 0.8 | 475 | 1.7 | 4.3 | 20 | 10 | |

| MDD 1.25-250 | 0.8x6.35 | 0.4x2 | 6.35 | 1.7 | 4.3 | 21 | 10 | |

| MDD 2-110(5) | 0.5x2.8 | 0.5 | 2.8 | 2.3 | 4.3 | 17.7 | 10 | Lead section:1.5~2. 5mm2 (A.W.G 16~14) Material: Brass Imax:15A |

| MDD 2-187(5) | 0.5x4.75 | 0.5 | 4.75 | 2.3 | 4.3 | 20 | 10 | |

| MDD 2-187(8) | 0.8x4.75 | 0.8 | 4.75 | 2.3 | 4.3 | 20 | 10 | |

| MDD 2-250 | 0.8x6.35 | 0.4x2 | 6.35 | 2.3 | 4.3 | 21 | 10 | |

| MDD 5.5-2.5 | 0.8x6.35 | 0.4x2 | 6.35 | 3.4 | 5.7 | 25 | 13 | Lead section:4~6nm2 (A. W.G 12~10) Material: Brass Imax:24A |

FDFN Nylon Fully Insulated Femal Terminal

| Material | PVC, Brass |

| Wire Size | Red:0.5~1.5mm2 Blue:1.5-2.5mm2 Yellow:4~6mm2 |

| Sample | Free |

MDFN Nylon Fully Insulated Mal Terminal

| Material | PVC, Brass |

| Wire Size | Red:0.5~1.5mm2 Blue:1.5~2.5mm2 Yellow:4~6mm2 |

| Sample | Free |

BV Fully Insulated Terminal

| BV Insulated connector | |||||||

| Model | Section of lead | Dimension (mm) | MAX current | Colour | |||

| A.W.G | mm2 | B(mm) | d(mm) | L(mm) | |||

| BV0.75 | 22-18 | 0.5-1.0 | 15 | 1.7 | 25.5 | 19A | Red |

| BV1.25 | 22-16 | 0.75-1.5 | 15 | 1.9 | 26 | 19A | Red |

| BV2 | 16-14 | 1.5-2.5 | 15 | 2.3 | 26 | 27A | Blue |

| BV3.5 | 14-12 | 2.5-4 | 15 | 3 | 26 | 37A | Black |

| BV5.5 | 12-10 | 4-6 | 15 | 3.4 | 26 | 48A | Yellow |

| BV8 | #8 | 6-10 | 21 | 4.5 | 35 | 62A | Red |

| BV14 | #6 | 10-16 | 26 | 5.8 | 42 | 88A | Blue |

| BV22 | #4 | 16-25 | 29 | 7.7 | 50 | 115A | Yellow |

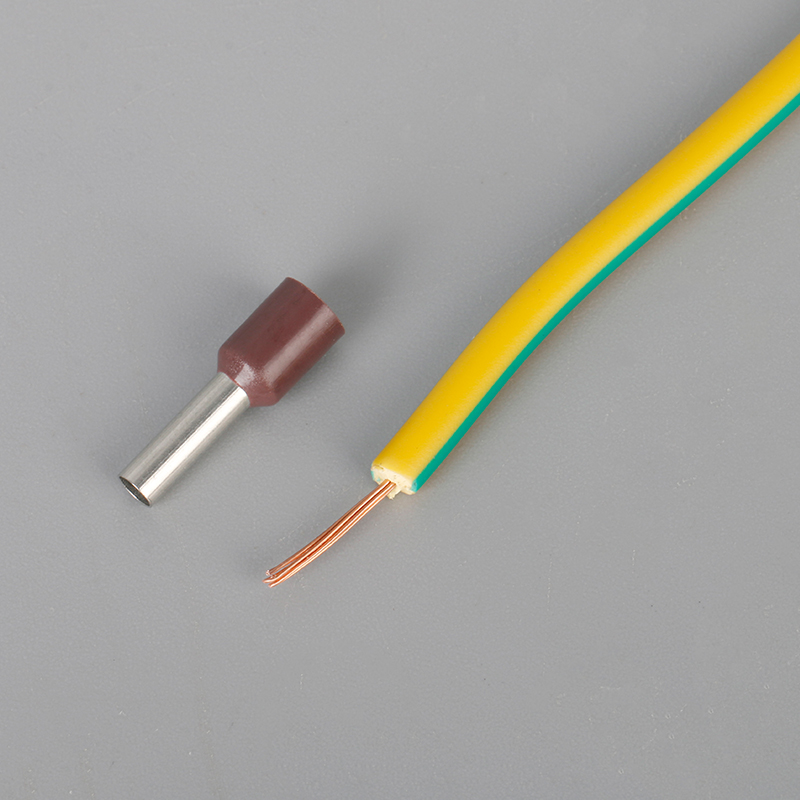

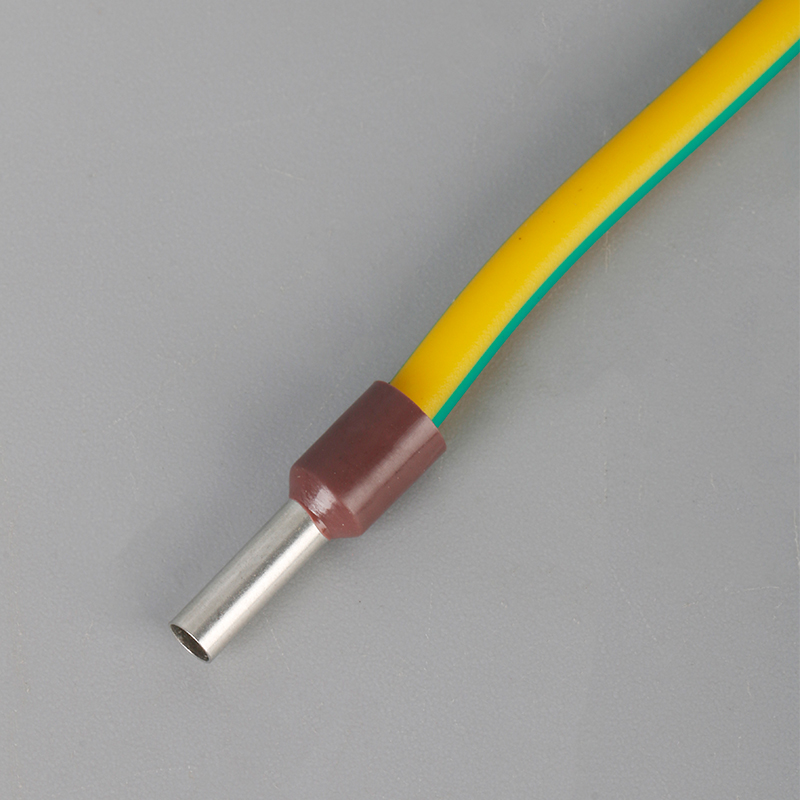

An insulated terminal is an electrical connector that consists of a metal part (typically copper) and an insulating sleeve (often made of plastic). The metal part is designed to be crimped onto a wire, while the insulating sleeve surrounds the connection, preventing accidental contact with other conductive parts. The insulation helps to reduce the risk of electrical shocks, short circuits, and other electrical hazards by preventing the exposed metal from coming into contact with external conductive surfaces.

1. Types of Insulated Terminals

Insulated terminals come in various types, each designed for specific applications and wire sizes. Below are some of the most common types:

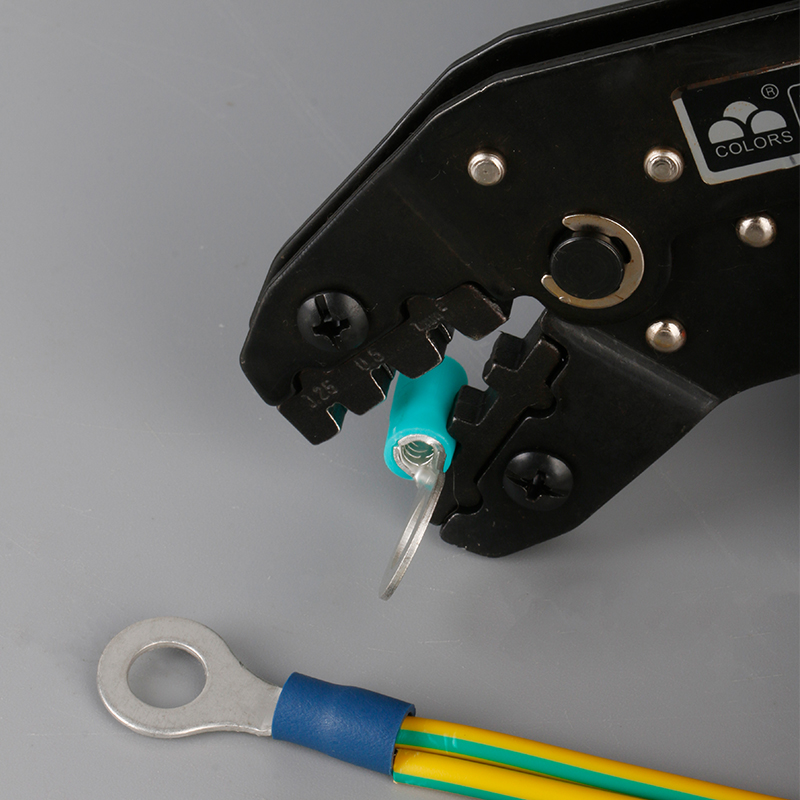

Ring Terminals: Ring terminals are designed to be attached to a stud or screw, offering a secure and stable connection. These are commonly used in automotive, industrial, and electrical applications where a bolted connection is required.

Spade Terminals: Spade terminals have a flat, fork-like shape that allows for easy attachment to a screw or stud. These are widely used in applications where quick connect and disconnect capabilities are needed, such as in electrical panels and circuit boards.

Butt Connectors: Butt connectors are designed to join two wires end-to-end, providing a secure and insulated connection. These are commonly used in automotive wiring and electrical installations where a simple, direct connection is needed.

Bullet Terminals: Bullet terminals feature a cylindrical shape and are typically used for quick connect and disconnect applications. They are ideal for automotive and machinery applications that require temporary connections.

Push-on Terminals: Push-on terminals feature a spring-loaded design that allows for easy attachment and removal without the need for tools. These are commonly used in applications where frequent connection and disconnection are required.

2. Key Features of Insulated Terminals

Insulation Protection: The key feature of insulated terminals is their insulating sleeve, which covers the metal part and prevents direct contact with other surfaces. This protects the user and surrounding components from electrical shock.

High Durability: Insulated terminals are made from high-quality materials that provide excellent resistance to heat, moisture, and chemicals, ensuring a long-lasting and reliable connection. The terminals can withstand harsh environmental conditions without degrading.

Secure Connection: Insulated terminals offer a secure and reliable electrical connection between the wire and other components in the circuit. The crimping process ensures a firm hold, reducing the risk of loose connections or interruptions in the electrical flow.

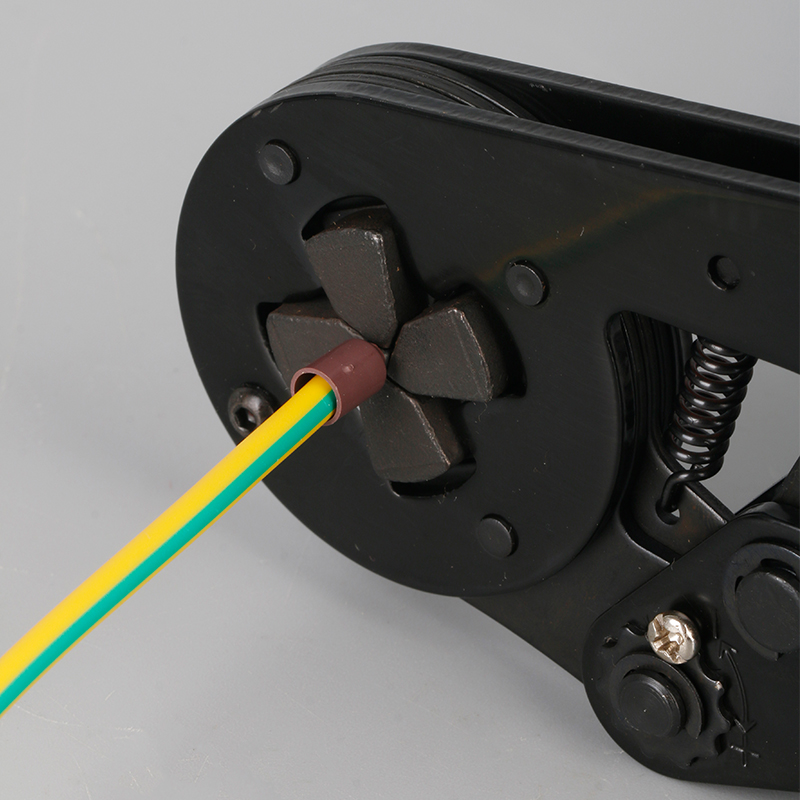

Ease of Use: These terminals are designed for easy installation, often requiring only a crimping tool to attach them securely to wires. The simplicity of installation makes them ideal for both DIY enthusiasts and professional electricians.

3. Advantages of Insulated Terminals

Reliability: Insulated terminals ensure a strong, secure, and stable electrical connection, reducing the chances of failure due to corrosion or loosening over time.

Wide Range of Applications: Insulated terminals are highly versatile and can be used in a variety of applications, from automotive wiring to industrial control systems and residential electrical installations.

Corrosion Resistance: The insulation also helps protect the metal part of the terminal from exposure to moisture, dust, and corrosive substances, prolonging its lifespan and maintaining the integrity of the electrical connection.

Cost-Effective: Insulated terminals are a cost-effective solution compared to other types of connectors. Their durability and ease of use reduce the need for frequent replacements and maintenance, ultimately saving money in the long run.

About Us

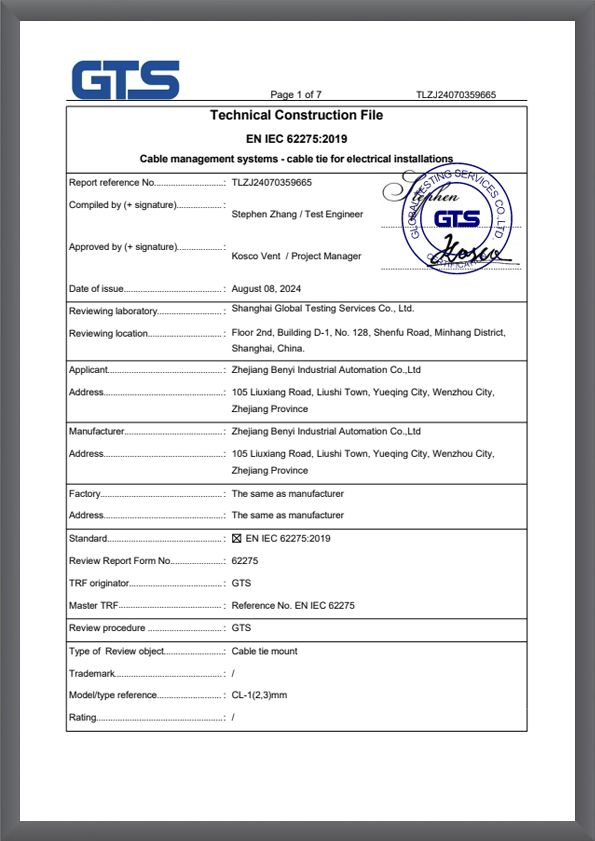

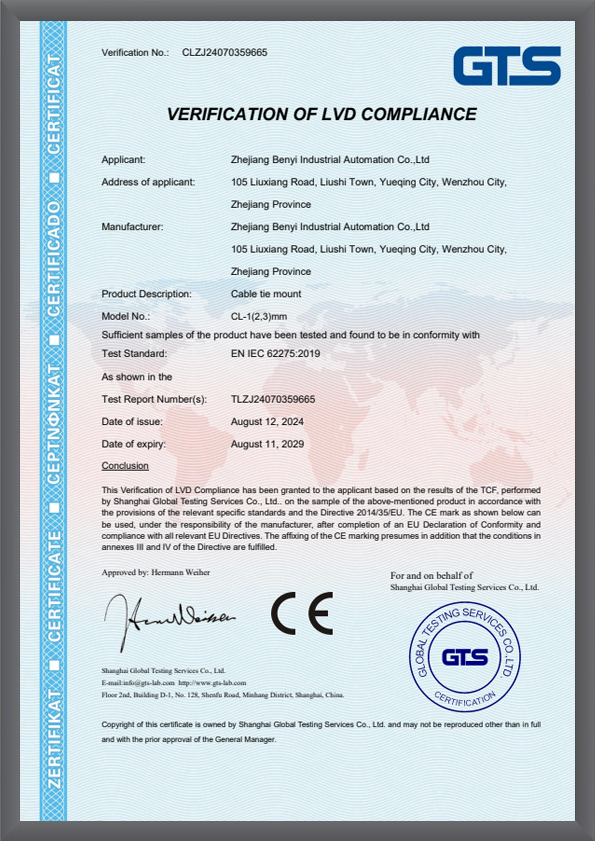

Honor

-

TLZJ24070359665

TLZJ24070359665 -

CLZJ24070359665

CLZJ24070359665 -

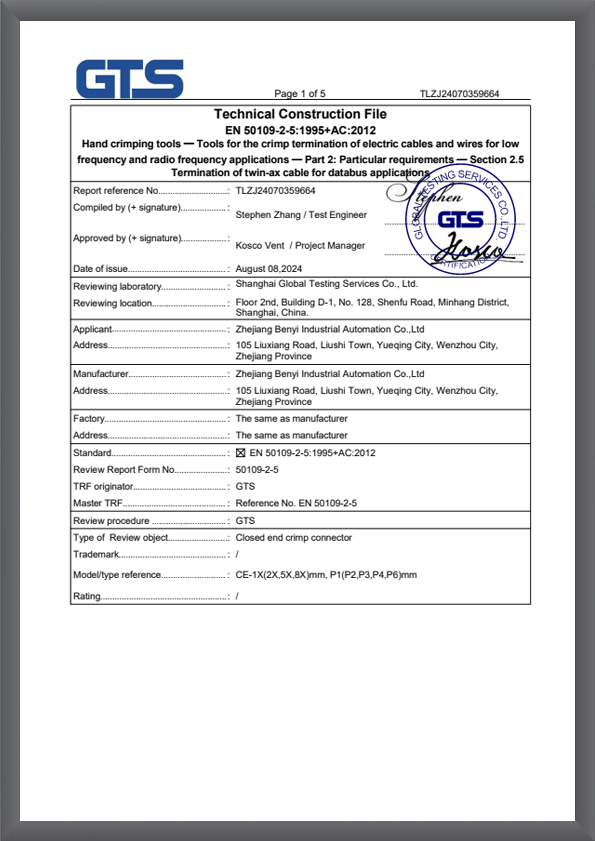

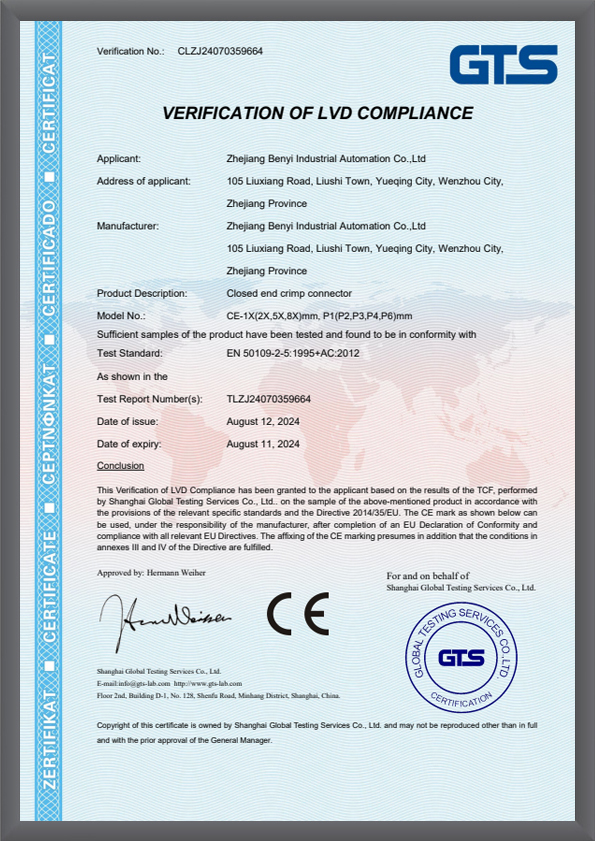

TLZJ24070359664

TLZJ24070359664 -

CLZJ24070359664

CLZJ24070359664 -

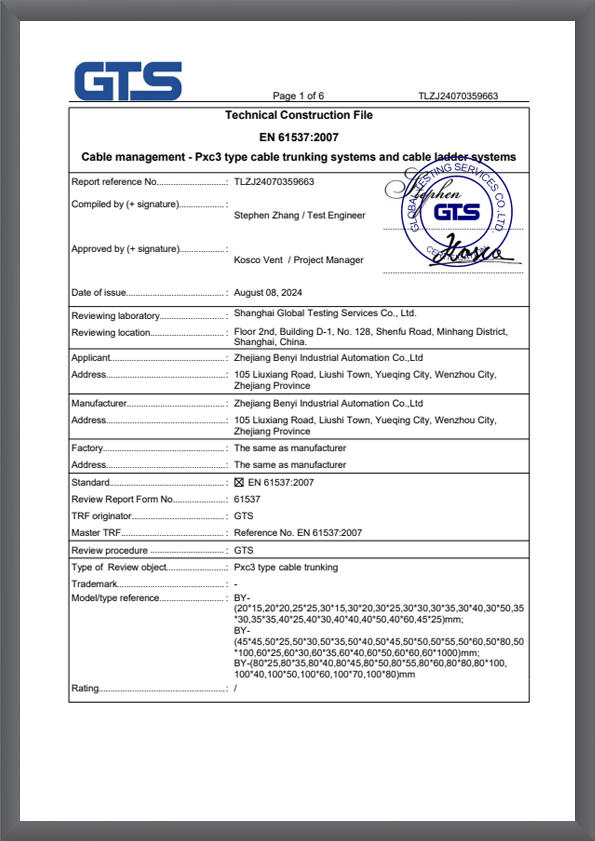

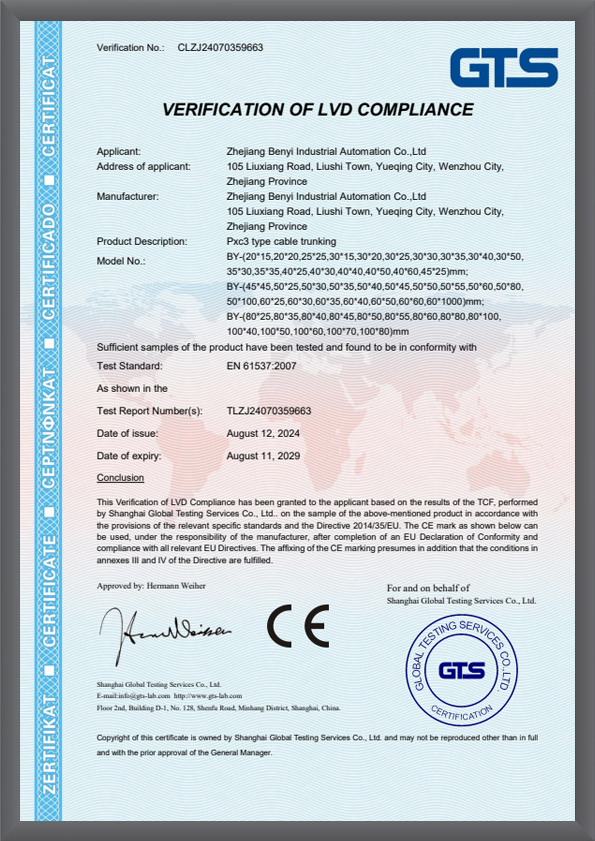

TLZJ24070359663

TLZJ24070359663 -

CLZJ24070359663

CLZJ24070359663

News

-

Industry News 2026-01-30

2:1 heat shrink tubes are widely used in industrial and electronic applications due to their ability to provide electrical insulation, mechanical prot...

View More -

Industry News 2026-01-23

Brass cable glands are essential components in industrial electrical systems. They secure cables as they enter equipment or enclosures, providing stra...

View More -

Industry News 2026-01-16

In industrial electrical installations, managing cables safely and efficiently is a crucial concern. One component that plays a significant role in th...

View More -

Industry News 2026-01-09

Waterproof cable glands are essential components in electrical and network installations, providing a secure interface where cables pass through enclo...

View More

Contact us now

+86-15558905711

+86-15558905711 +86-15057372736

+86-15057372736 [email protected]

[email protected] 105 Liuxiang Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province, China

105 Liuxiang Road, Liushi Town, Yueqing City, Wenzhou City, Zhejiang Province, China

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语